Title:

“Revolutionize Your Biscuit Production with State-of-the-Art Automatic Packing Line and Feeding System”

Description:

Introduction:

Welcome to our video showcasing the incredible capabilities of the Automatic Packing Line and Biscuit Feeding System. In this video, we will explore the features, benefits, and price of this cutting-edge technology that is set to transform the biscuit production industry. Prepare to be amazed!

Video Content:

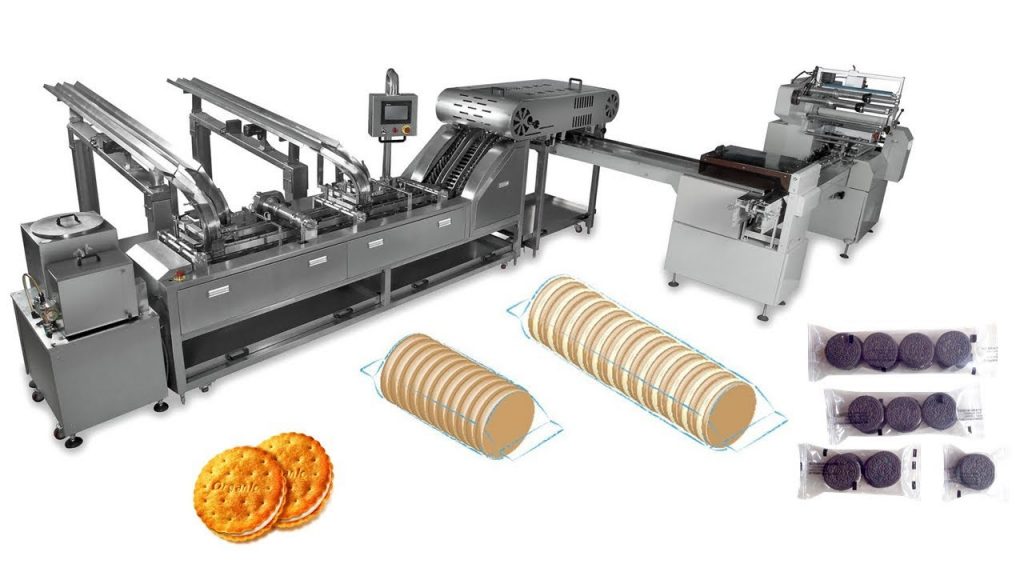

Our Automatic Packing Line is a game-changer in the biscuit production field. With its advanced technology and efficient design, it offers unparalleled speed, accuracy, and convenience. Say goodbye to tedious manual packing processes and hello to streamlined operations.

Key Highlights:

1. Enhanced Efficiency: Our Automatic Packing Line optimizes the packaging process, reducing labor costs and increasing productivity. It ensures consistent and precise packaging, minimizing errors and maximizing output.

2. Versatile Biscuit Feeding System: The integrated Biscuit Feeding System is specifically designed to handle various biscuit shapes and sizes effortlessly. It guarantees smooth and continuous feeding, eliminating disruptions in the production line.

3. Pillow Pack Machines: Our state-of-the-art Pillow Pack Machines provide a secure and attractive packaging solution for your biscuits. These machines ensure the highest level of hygiene and product safety, preserving the freshness and quality of your biscuits.

Operation Steps:

– Step 1: Biscuit Feeding System: Watch as the automated Biscuit Feeding System effortlessly transports biscuits from the production line to the Pillow Pack Machines.

– Step 2: Automated Packaging: Witness the seamless process of the Automatic Packing Line as it precisely packages the biscuits in the Pillow Pack Machines.

– Step 3: Quality Control: Learn about the built-in quality control measures that guarantee only the finest biscuits make it to the packaging stage.

– Step 4: Finished Product: See the final result of the packaging process, showcasing perfectly packed biscuits ready for distribution.

Call to Action:

If you are ready to take your biscuit production to the next level, don’t hesitate to invest in our Automatic Packing Line and Biscuit Feeding System. Like, subscribe, and share this video to spread the word about this incredible technology that can revolutionize your business.

Additional Tags and Keywords:

automatic packing line, biscuit production line, biscuit feeding system, pillow pack machines, automation, automatic packaging, efficiency, productivity, biscuit packaging, advanced technology, streamlining operations, quality control, production optimization

Hashtags:

#automation #biscuitproduction #packagingtechnology #advancedmachinery #efficiencyboost

Title: Streamlining Automatic Biscuit Production Line with On-Edge Packing and Pillow Pack Machines

Introduction:

The biscuit industry has witnessed significant growth in recent years, leading to the adoption of automated production lines. To further enhance efficiency, integrating on-edge packing and pillow pack machines into the biscuit feeding system can streamline the entire production process. This article explores the benefits and features of this innovative solution for automatic biscuit production lines.

1. Increased Efficiency:

By incorporating on-edge packing and pillow pack machines, the biscuit feeding system becomes more efficient. The on-edge packing line ensures precise alignment of biscuits, optimizing space utilization and reducing wastage. Additionally, the pillow pack machines efficiently wrap the biscuits, reducing packaging time and improving overall productivity.

2. Improved Product Quality:

The integration of on-edge packing and pillow pack machines ensures that biscuits maintain their shape and quality throughout the production process. The accurate alignment in the on-edge packing line prevents breakage or deformation, while the pillow pack machines provide airtight packaging, preserving the freshness and taste of the biscuits.

3. Versatility:

The automatic biscuit production line with on-edge packing and pillow pack machines offers versatility in packaging options. The pillow pack machines can handle various sizes and shapes of biscuits, allowing manufacturers to cater to different customer preferences. This flexibility enables businesses to meet diverse market demands and enhance customer satisfaction.

4. Easy Integration and Operation:

The on-edge packing line and pillow pack machines are designed for seamless integration into existing biscuit production lines. The machines can be easily installed and require minimal adjustments to start functioning. Moreover, the intuitive user interface ensures ease of operation, reducing the need for extensive training and enabling quick adoption.

5. Cost-Effective Solution:

Implementing on-edge packing and pillow pack machines in the biscuit feeding system presents a cost-effective solution for manufacturers. The increased efficiency and improved packaging quality reduce production losses and minimize material wastage. Additionally, the automated process eliminates the need for manual labor, resulting in long-term cost savings for businesses.

Conclusion:

Incorporating on-edge packing and pillow pack machines into the biscuit feeding system of an automatic production line offers numerous benefits for biscuit manufacturers. From increased efficiency and improved product quality to versatility and cost savings, this innovative solution streamlines the production process, enabling businesses to meet market demands effectively and maximize profitability. coil packing line

#Automatic #Biscuit #Production #Line #edge #Packing #line #Biscuit #Feeding #System #Pillow #Pack #Machines