Title: Efficient Sugar Packaging with the UNIVERSAL 1200 Automatic Bagging Machine

Description:

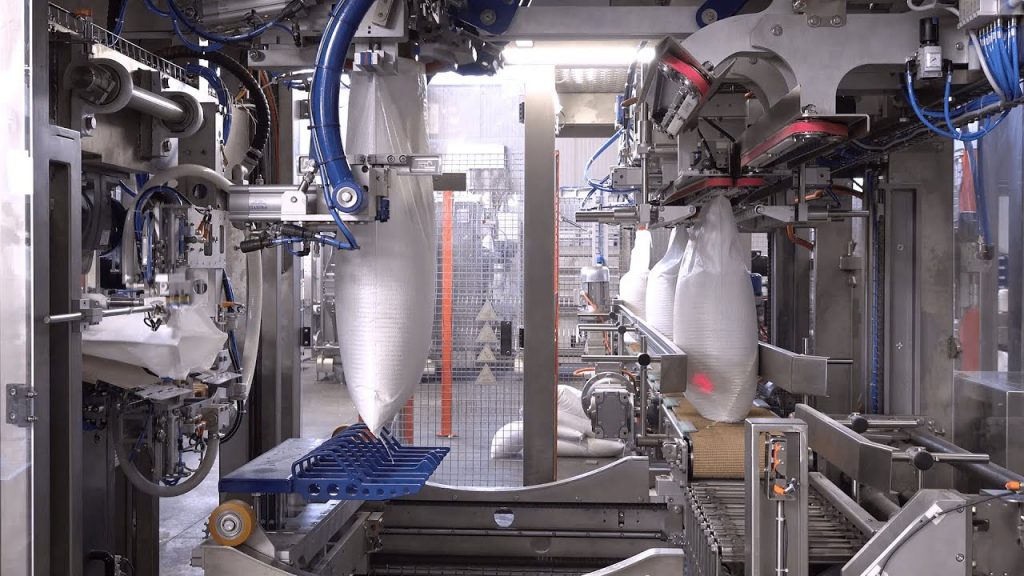

Welcome to our video showcasing the incredible capabilities of the UNIVERSAL 1200 Automatic Bagging Machine for packaging sugar efficiently. This state-of-the-art bagging machine is designed specifically for open mouth bagging, offering a range of features to streamline the packaging process.

In this video, we will take you through the step-by-step operation of the UNIVERSAL 1200 Automatic Bagging Machine. From start to finish, you will learn how this machine can effortlessly handle bag sizes ranging from 5 to 25 kg, making it perfect for sugar packaging applications.

Heading 1: Introduction

– Overview of the UNIVERSAL 1200 Automatic Bagging Machine’s role in the sugar packaging industry

– Highlighting the benefits of using an automated bagging system for increased efficiency and productivity

Heading 2: Key Features of the UNIVERSAL 1200 Automatic Bagging Machine

– Robust construction and user-friendly interface for easy operation

– Precise weighing and bag filling capabilities to ensure accurate packaging

– Versatile bag size range, accommodating 5 to 25 kg bags

– Efficient bag sealing mechanism for secure packaging

– Advanced technology for minimizing product waste and enhancing productivity

Heading 3: Step-by-Step Operation of the UNIVERSAL 1200 Automatic Bagging Machine

– Preparing the machine for operation and adjusting settings for specific bag sizes

– Loading sugar into the machine’s hopper and initiating the bagging process

– Weighing and filling the bags with the desired amount of sugar

– Seamlessly sealing the bags to maintain product integrity

– Safely removing the filled bags from the machine and preparing for distribution

Heading 4: Call to Action

If you found this video informative and helpful, please consider liking, subscribing, and sharing it with others in the industry. Stay updated with our latest videos on automatic bagging machines and packaging solutions by subscribing to our channel.

Additional Tags and Keywords: sugar packaging, bagging machine, automatic bagging system, UNIVERSAL 1200, efficient packaging, open mouth bagging, packaging technology, sugar industry, automated bagging

Hashtags: #SugarPackaging #BaggingMachine #Automation #Efficiency #PackagingSolutions #UNIVERSAL1200

Title: Efficient and Reliable Tilter for Sugar Automatic Bagging Machine – 5-25 Kg

Introduction:

Our tilter solution for the Sugar Automatic Bagging Machine is designed to enhance productivity, accuracy, and efficiency in the packaging process. With the ability to handle bag sizes ranging from 5 to 25 kg, our tilter ensures seamless bag positioning and precise filling, optimizing operations for sugar manufacturers.

1. Enhanced Bag Positioning:

Our tilter employs advanced technology to accurately position bags for filling. Equipped with sensor-based controls, it ensures that bags are aligned correctly, minimizing the risk of spillage or damage. This feature guarantees consistent bag placement, reducing downtime and increasing overall throughput.

2. Adjustable Weight Range:

The tilter accommodates bag sizes ranging from 5 to 25 kg, offering flexibility to sugar manufacturers. By adjusting the weight range, producers can easily switch between different bag sizes without the need for additional equipment, streamlining operations and reducing costs.

3. Automated Bag Tilting:

Our tilter automates the process of bag tilting, eliminating the need for manual labor and improving worker safety. With a user-friendly interface, operators can easily set the desired tilt angle, ensuring precise pouring of sugar into the bags. This automation feature significantly reduces the risk of human error, ensuring consistent and accurate filling.

4. High-Speed Bag Tilt:

Designed for high-volume production, our tilter delivers rapid bag tilting, minimizing cycle times and maximizing output. The quick tilt mechanism allows for efficient bag filling without compromising quality. This high-speed functionality is especially beneficial for sugar manufacturers with large-scale operations.

5. Durability and Easy Maintenance:

Built with robust materials, our tilter is designed to withstand demanding industrial environments. It requires minimal maintenance, reducing downtime and increasing overall equipment efficiency. With a focus on durability, our tilter ensures long-term reliability for continuous bagging operations.

Conclusion:

Our tilter for the Sugar Automatic Bagging Machine – 5-25 Kg offers a comprehensive solution for sugar manufacturers, improving bag positioning, reducing manual labor, and increasing production efficiency. With its adjustable weight range, automated tilting, and high-speed functionality, this tilter ensures precise and reliable bag filling, enhancing overall productivity for sugar packaging operations. coil packing line

#Sugar #Automatic #Bagging #Machine