Check out the leading manufacturer for all your coil packing solution needs here:

—

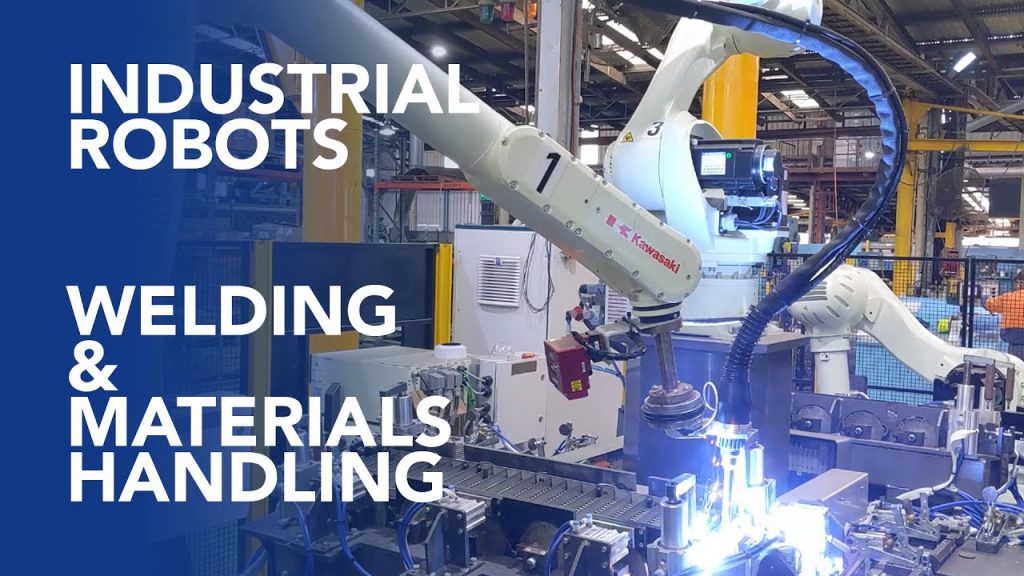

Title: How Industrial Robotics Revolutionize Manufacturing Efficiency

Introduction:

In today’s fast-paced manufacturing industry, efficiency, productivity, repeatability, and scalability are crucial factors for success. Manufacturers are constantly seeking innovative solutions to streamline their processes and stay ahead of the competition. This is where industrial robotics, specifically industrial handling machines, come into play. In this article, we will explore how these advanced machines have revolutionized the manufacturing landscape and discuss their benefits for manufacturers.

—

Opinion/Thought Piece Style:

Industrial handling machines have become a game-changer for manufacturers worldwide. These state-of-the-art robots are designed to handle various tasks, from material handling to welding and everything in between. With their advanced capabilities, they offer a level of precision and efficiency that was once unimaginable.

One of the key advantages of industrial handling machines is their ability to increase efficiencies. These robots can perform tasks with unparalleled speed and accuracy, eliminating human errors and reducing production time. With the help of sophisticated sensors and algorithms, they can optimize the entire manufacturing process, from start to finish.

Moreover, industrial handling machines enhance productivity by automating repetitive tasks. These machines can operate 24/7 without fatigue or breaks, ensuring a continuous workflow. By taking over mundane and repetitive tasks, they free up human workers to focus on more complex and creative aspects of production.

Repeatability is another crucial aspect that industrial handling machines excel at. With their precise programming, they can consistently perform tasks with the same level of accuracy, ensuring consistent product quality. This is particularly important for industries that require strict adherence to quality standards, such as automotive or electronics manufacturing.

Scalability is yet another advantage offered by industrial handling machines. As businesses grow and demand increases, these robots can easily be integrated into existing production lines or expanded to handle higher volumes. This flexibility allows manufacturers to adapt to changing market conditions and meet customer demands efficiently.

—

Explanatory Style:

To understand the impact of industrial handling machines, let’s take a closer look at some specific applications. One such application is welding. Industrial robotics have transformed the welding process, making it faster, more precise, and safer. These robots can weld complex patterns with extreme accuracy, ensuring strong and consistent welds. With their ability to handle repetitive welding tasks, they significantly improve productivity while maintaining high-quality standards.

Another application where industrial handling machines shine is materials handling. In industries like logistics and warehousing, these robots are revolutionizing the way goods are moved and stored. With their advanced sensors and algorithms, they can navigate through complex environments, avoiding obstacles and optimizing the movement of materials. This not only increases efficiency but also minimizes the risk of accidents and injuries.

—

Narrative Style:

Imagine a bustling factory floor, where workers are engaged in various tasks, from packaging to assembly. In the past, these tasks required human intervention, which often led to errors and delays. However, with the introduction of industrial handling machines, the dynamics have changed.

Meet the industrial handling machine, a highly sophisticated robot capable of performing a wide range of tasks. With its powerful arms and precise programming, it can lift heavy objects, sort materials, and even assemble intricate components. These robots work tirelessly, day and night, without the need for breaks or rest.

In one corner of the factory, the industrial handling machine is busy packaging products. With its lightning-fast speed and accuracy, it swiftly picks up items, places them in boxes, and seals them shut. This level of efficiency ensures that the packaging process is completed in record time, saving valuable resources and reducing costs.

—

Check the coil packing solution with leading manufacturer for the professional solution just here: Handling Machine

“Streamlining Industrial Processes: Enhancing Efficiency with Robotics in Welding, Materials Handling, and Industrial Machine Operations”