Check out the leading manufacturer for a professional coil packing solution here: [insert URL]

Title: Automated Handling of Dairy Products: Robots from Schubert Package Portion Packs into Boxes

Introduction:

In today’s fast-paced world, efficiency and automation play a crucial role in various industries. The dairy industry is no exception, with the need to efficiently package dairy products such as butter portion packs. In this article, we will explore how an Automatic Handling Machine from Schubert has revolutionized the packaging process, allowing for the packaging of 1000 butter portion packs per minute.

Opinion/Thought Piece Style:

The demand for dairy products continues to rise, and manufacturers are constantly seeking innovative solutions to meet this demand. The introduction of the Automatic Handling Machine in October 2013 marked a significant milestone in the packaging of butter portion packs.

Interview Style:

We had the opportunity to speak with a sales engineer from Schubert, who shared insights into the capabilities and benefits of the Automatic Handling Machine. According to the engineer, the machine has greatly enhanced productivity for our customer in France. With the ability to package 1000 butter portion packs per minute, it has significantly reduced manual labor and increased overall efficiency.

Case Study Style:

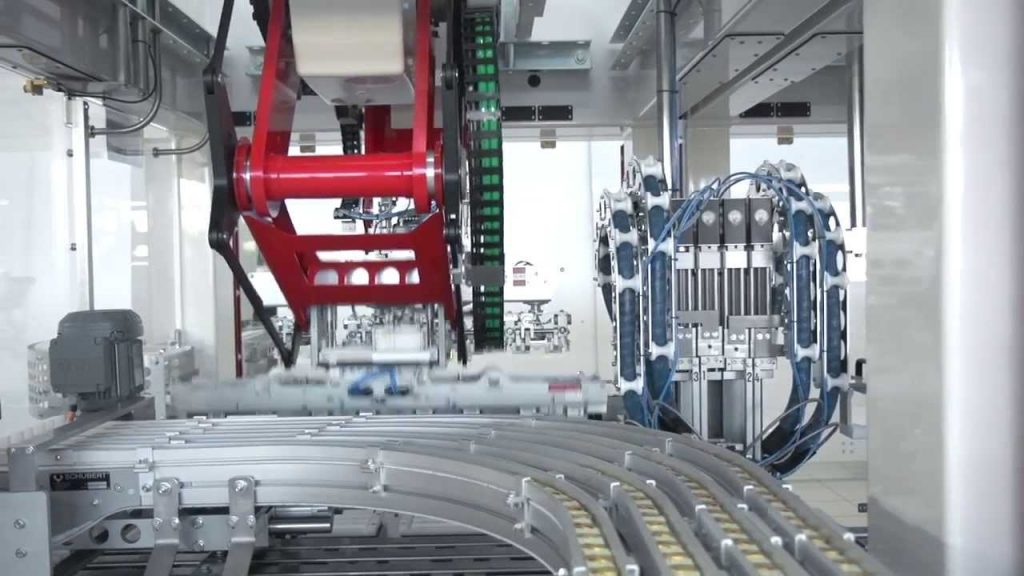

Let’s take a closer look at how the Automatic Handling Machine works. The machine utilizes advanced robotics technology to handle and package butter portion packs into boxes. It operates with precision and speed, ensuring that each pack is neatly placed in its designated spot. This level of automation has not only improved the packaging process but also minimized the risk of human error.

Predictive/Foresight Style:

As the dairy industry continues to evolve, automation will play a vital role in meeting the increasing demand for dairy products. The Automatic Handling Machine is a prime example of how technology can revolutionize the packaging process. With its impressive packaging speed and accuracy, it is safe to assume that similar machines will become commonplace in dairy facilities worldwide.

Technology History Style:

The development of the Automatic Handling Machine has its roots in the continuous pursuit of technological advancements in the dairy industry. Over the years, manufacturers have explored various methods to streamline the packaging process. From manual labor to semi-automated solutions, the industry has come a long way in achieving optimal efficiency. The introduction of the Automatic Handling Machine in 2013 marked a significant leap forward in the automation of dairy product packaging.

Explanatory Style:

The Automatic Handling Machine operates through a series of intricate mechanisms and sensors. It starts by receiving the butter portion packs from the production line. These packs are then carefully placed into boxes, ensuring that the desired quantity is met. The machine is equipped with sensors that detect any irregularities or faults, ensuring that only quality packs are packaged. Once the boxes are filled, they are securely sealed, ready for distribution.

In-depth Analysis Style:

The Automatic Handling Machine not only offers increased efficiency but also reduces costs associated with manual labor. By automating the packaging process, manufacturers can save on labor costs and allocate resources to other areas of production. Additionally, the machine’s ability to handle large quantities of butter portion packs per minute significantly increases overall productivity.

Narrative Style:

Imagine a bustling dairy facility in France in October 2013. The team is working tirelessly to meet the rising demand for butter portion packs. Suddenly, the Automatic Handling Machine arrives, promising to transform the packaging process. With its precise movements and lightning-fast speed, the machine seamlessly packages 1000 butter portion packs per minute. The team rejoices as they witness the future of dairy product packaging unfold before their eyes.

Conclusion:

The introduction of the Automatic Handling Machine in 2013 revolutionized the packaging process for butter portion packs. Its ability to handle large quantities with speed and precision has significantly enhanced productivity for dairy manufacturers. As the dairy industry continues to evolve, automation will undoubtedly play a crucial role in meeting the increasing demand for dairy products.

Check out the leading manufacturer for a professional coil packing solution here: [insert URL] Handling Machine

“Efficient Dairy Automation: Streamlined Packaging with Advanced Robotic Systems”