Title: Ultimate Guide to JXC Automatic Battery PACK Assembly Line for E-Vehicles, E-Bikes, E-Tools, and Energy Storage

Description:

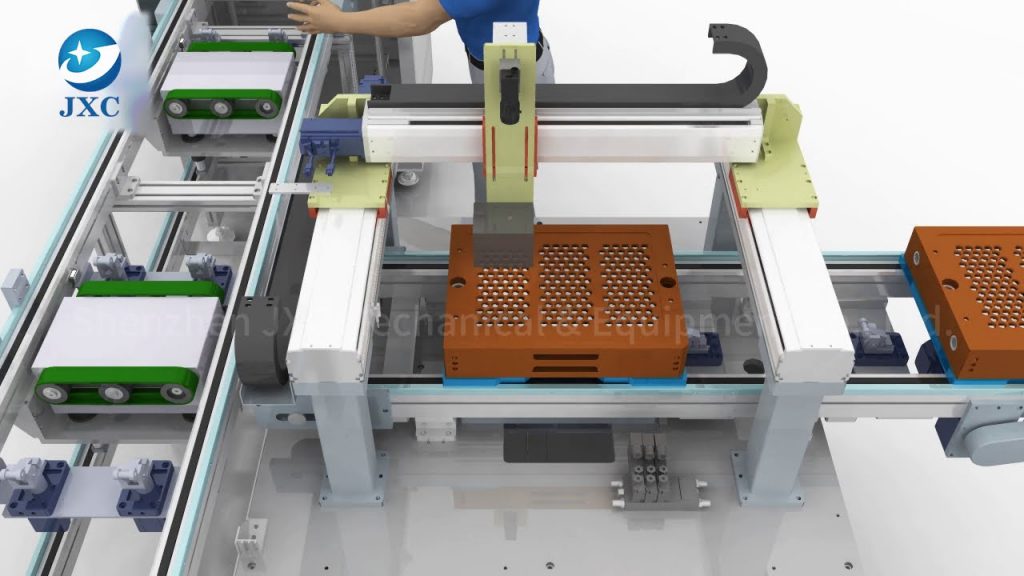

Welcome to the ultimate guide on JXC Automatic Battery PACK Assembly Line, designed specifically for E-Vehicles, E-Bikes, E-Tools, and Energy Storage. In this comprehensive video, we will delve into the intricate details of this cutting-edge technology, exploring its features, benefits, and operation steps.

Introduction:

Discover the revolutionary JXC Automatic Battery PACK Assembly Line, an innovation that has transformed the manufacturing process for battery packs used in E-Vehicles, E-Bikes, E-Tools, and Energy Storage. With our expertise and specialization in machines of battery production, JXC Mechanical & Equipment Co., Ltd. brings you this state-of-the-art assembly line.

Video Content:

In this video, we will take you on a journey through the various aspects of the JXC Automatic Battery PACK Assembly Line. We will explore its advanced features, including precise automation, high-speed production, and exceptional efficiency. Witness how this assembly line streamlines the manufacturing process, significantly reducing production time and costs.

Our expert team will guide you through the operation steps of the assembly line, demonstrating its ease of use and seamless integration into existing production setups. Gain insight into the quality control measures implemented to ensure each battery pack meets the highest industry standards.

Key Highlights:

– Advanced automation technology for enhanced productivity

– High-speed production capabilities for efficient manufacturing

– Seamless integration into existing production setups

– Excellent quality control measures for superior battery pack performance

Call to Action:

If you found this video informative and engaging, we encourage you to like, subscribe, and share it with your network. Stay updated with the latest advancements in battery pack assembly technology by subscribing to our channel.

Additional Tags and Keywords:

Automatic Packing Line Manufacturers, JXC Automatic Battery PACK Assembly Line, E-Vehicles, E-Bikes, E-Tools, Energy Storage, battery production, manufacturing process, automation technology, high-speed production, quality control measures, industry standards

Hashtags:

#AutomaticPackingLine #BatteryAssemblyLine #EVehicles #EBikes #ETools #EnergyStorage #JXCMechanical #BatteryProduction

Title: JXC Automatic Battery Pack Assembly Line: Revolutionizing E-Vehicles, E-Bikes, E-Tools, and Energy Storage

Introduction:

The JXC Automatic Battery Pack Assembly Line is an innovative solution designed to streamline the production process for manufacturing battery packs used in various electric vehicles (E-Vehicles), E-Bikes, E-Tools, and energy storage systems. This state-of-the-art assembly line incorporates cutting-edge technology and automation to ensure efficient and high-quality battery pack assembly, catering to the ever-growing demand in the electric mobility industry.

1. Enhanced Efficiency:

The JXC Automatic Battery Pack Assembly Line optimizes the production process, significantly improving efficiency. With advanced robotics and automation, this assembly line minimizes human error and maximizes productivity, resulting in consistent output, reduced cycle times, and increased production rates. Manufacturers can achieve higher production volumes without compromising on quality.

2. Customizable for Diverse Applications:

The assembly line is designed to accommodate a wide range of battery pack configurations, making it suitable for various applications such as E-Vehicles, E-Bikes, E-Tools, and energy storage systems. The system’s flexibility allows manufacturers to easily adapt to different battery pack sizes, chemistries, and configurations, ensuring compatibility with diverse product lines.

3. Quality Assurance:

The JXC Automatic Battery Pack Assembly Line integrates advanced quality control mechanisms to ensure the production of high-quality battery packs. With precise monitoring and testing at each stage of the assembly process, manufacturers can identify and rectify any defects or inconsistencies, ensuring the final product meets the highest standards of safety, reliability, and performance.

4. Cost-Effective Production:

By automating the assembly process, manufacturers can significantly reduce labor costs while maintaining consistent quality. The JXC Assembly Line minimizes the need for manual intervention, allowing businesses to allocate resources more efficiently and reduce operational expenses. Additionally, the system’s reliability and low maintenance requirements contribute to long-term cost savings.

5. Scalability and Future-Proofing:

The JXC Assembly Line is designed with scalability in mind, providing manufacturers with the flexibility to expand their production capacity as demand increases. This future-proof solution enables seamless integration of new technologies and advancements in battery pack assembly, ensuring manufacturers can adapt to evolving industry standards and stay ahead of the competition.

Conclusion:

The JXC Automatic Battery Pack Assembly Line revolutionizes battery pack production for E-Vehicles, E-Bikes, E-Tools, and energy storage systems. By leveraging cutting-edge technology, automation, and quality control mechanisms, this assembly line offers enhanced efficiency, customization, cost-effectiveness, and scalability. Manufacturers can rely on the JXC Assembly Line to meet the increasing demand for electric mobility solutions while maintaining the highest standards of quality and performance. coil packing line

#JXC #Automatic #Battery #PACK #Assembly #Line #EVehicles #EBikesEToolsEnergy #storage