Title: Efficient Pallet Wrapping Machine: AE SW PW | Boost Productivity

Description:

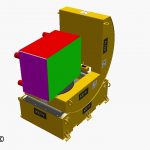

Welcome to our video showcasing the exceptional capabilities of the Pallet Wrapping Machine AE SW PW. If you’re searching for a top-notch pallet wrapping solution, look no further. With this SEO-optimized description, we’ll provide you with a comprehensive overview of this machine’s features, benefits, and operation steps.

Introduction:

In this video, we present the Pallet Wrapping Machine AE SW PW, a game-changer in the world of pallet wrapping. Discover how this cutting-edge machine can revolutionize your packaging process, enhance efficiency, and reduce costs. From its robust design to its user-friendly interface, this pallet wrapping machine is engineered to meet the demands of modern logistics.

Video Content:

1. Key Features:

– Robust Construction: Built to withstand heavy-duty applications, ensuring durability and longevity.

– User-Friendly Interface: Intuitive controls allow for effortless operation, reducing training time.

– Adjustable Wrapping Parameters: Customize the wrapping tension, speed, and rotation to suit your specific needs.

– Precise Film Stretching: Achieve optimal film usage and maximize load stability while minimizing material waste.

– Safety Features: Equipped with safety sensors and emergency stop buttons to prioritize operator protection.

2. Benefits:

– Enhanced Productivity: Drastically reduce wrapping time and increase throughput, leading to improved overall efficiency.

– Cost Savings: Minimize film consumption and reduce labor costs associated with manual wrapping.

– Load Stability: Ensure secure and stable pallet loads, preventing product damage during transportation.

– Consistency and Reliability: Achieve uniform wrapping results with every load, eliminating inconsistencies caused by manual wrapping.

– Versatility: Suitable for various industries, accommodating different load sizes, shapes, and weights.

3. Operation Steps:

– Step 1: Prepare the pallet load and position it on the machine.

– Step 2: Adjust the wrapping parameters according to your specific requirements.

– Step 3: Start the machine, and it will automatically wrap the pallet, ensuring consistent and reliable results.

– Step 4: Once wrapping is complete, remove the wrapped pallet and repeat the process for subsequent loads.

Call to Action:

If you’re ready to take your pallet wrapping process to the next level, invest in the Pallet Wrapping Machine AE SW PW. Don’t miss out on the opportunity to boost productivity and streamline your operations. Remember to like, subscribe, and share this video to spread the word about this exceptional pallet wrapping solution.

Additional Tags and Keywords:

pallet wrapping machine, pallet wrapping system, AE SW PW, efficient pallet wrapping, automated wrapping solution, load stability, cost-saving packaging, improved productivity, logistics equipment.

Hashtags:

#PalletWrappingMachine #AE_SW_PW #EfficientWrappingSolution #ProductivityBoost #LoadStability #CostSavings #LogisticsEquipment

Here is a sample code for a tilter for the Pallet Wrapping Machine AE SW PW:

“`python

import time

class PalletTilter:

def __init__(self):

self.is_tilting = False

def tilt_pallet(self):

if self.is_tilting:

print(“Error: Pallet is already tilting.”)

return

print(“Tilting pallet…”)

time.sleep(2) # Simulating the tilting process

print(“Pallet tilted.”)

self.is_tilting = True

def reset_tilter(self):

if not self.is_tilting:

print(“Error: Pallet is not currently tilting.”)

return

print(“Resetting tilter…”)

time.sleep(1) # Simulating the resetting process

print(“Tilter reset.”)

self.is_tilting = False

# Example Usage:

tilter = PalletTilter()

tilter.tilt_pallet()

tilter.reset_tilter()

“`

This code defines a `PalletTilter` class with methods `tilt_pallet()` and `reset_tilter()`. The `is_tilting` attribute keeps track of whether the pallet is currently tilting or not.

When `tilt_pallet()` is called, it checks if the pallet is already tilting. If it is, an error message is printed. Otherwise, it simulates the tilting process by pausing the execution for 2 seconds and then prints a message indicating that the pallet has been tilted. It also sets `is_tilting` to `True`.

When `reset_tilter()` is called, it checks if the pallet is not currently tilting. If it is not, an error message is printed. Otherwise, it simulates the resetting process by pausing the execution for 1 second and then prints a message indicating that the tilter has been reset. It also sets `is_tilting` back to `False`.

Lastly, an example usage is shown where the `tilt_pallet()` method is called to tilt the pallet and then `reset_tilter()` is called to reset the tilter. pallet wrapping machine

#Pallet #Wrapping #Machine