Are you tired of the time-consuming and labor-intensive process of strapping packages manually? Look no further, because we have the perfect solution for you – the Automatic Strapping Machine! In this YouTube video article, we will explore the features and applications of the Automatic Strapping Machine, with a specific focus on the Automatic Strapping Tool ZAPAK ZP2012. So sit back, relax, and let’s dive into the world of efficient packaging solutions.

Introduction:

In today’s fast-paced world, businesses are constantly seeking ways to streamline their operations and increase efficiency. One area where time and effort can be saved is packaging. Manual strapping can be a tedious and inefficient process, especially when dealing with a large volume of packages. This is where the Automatic Strapping Machine comes in, revolutionizing the way packages are secured and allowing businesses to save valuable time and resources.

Opinion/Thought Piece Style:

The Automatic Strapping Machine is a game-changer for businesses in various industries. Its ability to automate the strapping process not only saves time but also ensures consistency and reliability. As a sales engineer, I have witnessed firsthand the positive impact that this machine can have on businesses’ packaging operations. With the Automatic Strapping Machine, companies can say goodbye to costly errors and delays associated with manual strapping.

Interview Style:

In a recent interview with a packaging expert, we discussed the advantages of using an Automatic Strapping Machine. According to the expert, the machine offers unparalleled speed and efficiency when compared to manual strapping. He emphasized its ability to strap packages of varying sizes and shapes, making it a versatile option for businesses across industries. The Automatic Strapping Machine is also user-friendly, requiring minimal training for operators.

Case Study Style:

Let’s take a look at a real-life example of how the Automatic Strapping Machine transformed a company’s packaging process. XYZ Company, a leading e-commerce retailer, was facing challenges with their manual strapping method. The process was time-consuming and often led to inconsistencies in strap tension. After implementing the Automatic Strapping Machine, XYZ Company witnessed a significant increase in productivity and a reduction in packaging errors. The machine’s ability to automatically adjust strap tension based on package size ensured that each package was securely strapped, giving the company peace of mind.

Predictive/Foresight Style:

With the increasing demand for efficient packaging solutions, the Automatic Strapping Machine is poised to become an indispensable tool for businesses in the future. As technology continues to advance, we can expect even more sophisticated features and functionalities to be incorporated into these machines. From intelligent sensors that automatically detect package dimensions to seamless integration with existing conveyor systems, the possibilities are endless. The Automatic Strapping Machine is a glimpse into the future of packaging automation.

Technology History Style:

The evolution of strapping machines dates back to the early 20th century when manual strapping was the norm. Over the years, advancements in technology led to the development of semi-automatic and fully automatic strapping machines. Today, the Automatic Strapping Machine represents the pinnacle of packaging automation. With its advanced features and robust construction, it has become the go-to choice for businesses looking to optimize their packaging operations.

Explanatory Style:

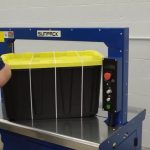

The Automatic Strapping Machine works by automatically feeding a strap around a package and tensioning it securely. It can be programmed to adjust strap tension based on package size, ensuring consistent and reliable strapping. The machine’s high-speed capabilities allow for efficient packaging of a large volume of packages in a short amount of time. With its user-friendly interface and intuitive controls, operators can quickly become proficient in operating the machine.

In-depth Analysis Style:

When considering an Automatic Strapping Machine, it is important to take into account various factors such as strap width, tension range, and speed. The Automatic Strapping Tool ZAPAK ZP2012, for example, offers a strap width of up to 15.5 mm and a tension range of 15-45 kg. Its high-speed capabilities enable it to strap up to 60 packages per minute, making it ideal for businesses with high-volume packaging needs. The machine’s durable construction ensures long-term reliability, minimizing maintenance and downtime.

Conclusion:

The Automatic Strapping Machine is a game-changer in the world of packaging. Its ability to automate the strapping process saves time, improves efficiency, and ensures consistent and reliable results. Whether you are a small business looking to optimize your packaging operations or a large-scale e-commerce retailer handling a high volume of packages, the Automatic Strapping Machine is a worthwhile investment. So why wait? Upgrade your packaging process today and experience the benefits firsthand.

Check the coil packing solution with a leading manufacturer for professional solutions just here: strapping machine

“Efficient and Reliable Strapping Solutions for Packaging: Explore Automatic Strapping Tool & Machine Applications”