Title: Ultimate Guide to the Automatic Bagging Packing Line – Efficiently Pack 50lb. Bags of Alfalfa Pellets

Description:

Welcome to our comprehensive guide on the Automatic Bagging Packing Line – the ultimate solution for efficiently packaging 50lb. bags of nutrient-rich alfalfa pellets. Whether you’re a feed mill owner, a distributor, or a farmer, this automated feed bagging system will revolutionize your packaging process, saving you time and increasing productivity.

At [Company Name], we specialize in providing cutting-edge industrial solutions, and our Automatic Bagging Packing Line ensures seamless bagging operations. This high-speed system quickly fills multi-wall paper bags with precisely 50lbs. of alfalfa pellets, guaranteeing accuracy and consistency in every bag.

Video Content:

In this video, we delve into the operation steps of the Automatic Bagging Packing Line, demonstrating its advanced features and highlighting the benefits it offers. Our experienced team will guide you through the entire bagging process, showcasing its efficiency, reliability, and user-friendly interface.

Key Highlights:

1. High-Speed Bag Filling: Witness the rapid bag filling capabilities of our system, which can handle a large volume of 50lb. bags per hour, streamlining your packaging operation.

2. Precision and Accuracy: Learn how our automated feed bagging system ensures precise weighing and filling, eliminating variations and minimizing product waste.

3. Multi-Wall Paper Bags: Explore the advantages of utilizing multi-wall paper bags, known for their durability and ability to preserve the quality of alfalfa pellets during storage and transportation.

4. User-Friendly Interface: Discover how our system’s intuitive interface makes operation hassle-free, reducing the need for extensive training and enabling quick adaptation.

5. Increased Productivity: Understand how the Automatic Bagging Packing Line optimizes your packaging process, resulting in enhanced productivity and cost savings.

Call to Action:

If you found this video informative, don’t forget to like, subscribe, and share it with others who may benefit from this advanced bagging solution. Feel free to leave any questions or comments below.

Additional Tags and Keywords:

Automated Feed Bagging System, Bagging Solutions, Industrial Bagging Equipment, Alfalfa Pellets Packaging, High-Speed Bag Filling, Multi-Wall Paper Bags, Efficient Packaging Process, Increase Productivity, Precision Weighing, User-Friendly Interface

Hashtags:

#AutomaticBaggingPackingLine #FeedBaggingSystem #AlfalfaPellets #EfficientPackaging #IndustrialSolutions #IncreaseProductivity

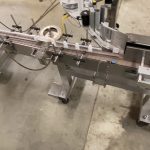

Here is a sample tilter for an Automated Feed Bagging System for 50lb. bags of Alfalfa Pellets:

Title: Automated Feed Bagging System Tilter for 50lb. Bags of Alfalfa Pellets

Objective:

The objective of this tilter is to design and implement an automated system that can tilt 50lb. bags of Alfalfa Pellets to ease the bagging process in a feed production facility.

Specifications:

1. Capacity: The tilter should be able to handle 50lb. bags of Alfalfa Pellets efficiently and without causing damage to the bags or the pellets.

2. Automation: The system should be fully automated, requiring minimal human intervention, to increase productivity and reduce labor costs.

3. Safety: The tilter should prioritize safety by incorporating safety mechanisms to prevent accidents or injuries to operators.

4. Durability: The tilter should be designed with sturdy materials to withstand the continuous operation and the weight of the bags.

5. Speed and Efficiency: The tilter should have a high processing speed to maintain a smooth production flow and meet production targets.

Components and Functionalities:

1. Bag Loading: The system should have a conveyor belt or similar mechanism to transport the bags to the tilter.

2. Tilt Mechanism: The tilter should be able to tilt the bags to a specific angle, allowing the Alfalfa Pellets to flow smoothly into the bagging machine.

3. Bag Support: The tilter should provide support to the bags during the tilting process to prevent damage or spillage.

4. Control Panel: The tilter should have a user-friendly control panel to set the desired tilt angle and monitor the operation.

5. Safety Features: The tilter should include safety sensors, emergency stop buttons, and protective guards to ensure the safety of operators.

6. Integration: The tilter should be easily integrated into the existing feed production line, ensuring smooth workflow and compatibility with other machines.

Testing and Quality Assurance:

1. The tilter should undergo rigorous testing to ensure it meets the required specifications and functionalities.

2. Quality checks should be conducted during the manufacturing process to ensure the tilter is built with high-quality materials and components.

3. Regular maintenance and inspections should be carried out to identify and rectify any issues promptly.

4. Operators should be trained on the proper operation and maintenance of the tilter to ensure optimal performance and longevity.

Conclusion:

This tilter for an Automated Feed Bagging System for 50lb. bags of Alfalfa Pellets aims to streamline the bagging process, increase productivity, and enhance safety in the feed production facility. By incorporating automation, durability, and safety features, this tilter ensures efficient and reliable bag tilting operations, ultimately contributing to the overall success of the feed production process. coil packing line

#Automated #Feed #Bagging #System #50lb #bags #Alfalfa #Pellets