Check out our leading manufacturer for a professional coil packing solution here: [insert manufacturer’s name or website].

Title: Revolutionizing Plastic Bowl Production with Industrial Plastic Injection Machines

Introduction:

In today’s fast-paced manufacturing industry, industrial plastic injection machines have emerged as a game-changer, transforming the way plastic products are produced. This article explores the remarkable capabilities of these machines and their role in customized plastic bowl making through injection molds. Join us as we delve into the world of plastic injection molding machines and discover how they have revolutionized the manufacturing sector.

I. Industrial Plastic Injection Machine: An Overview

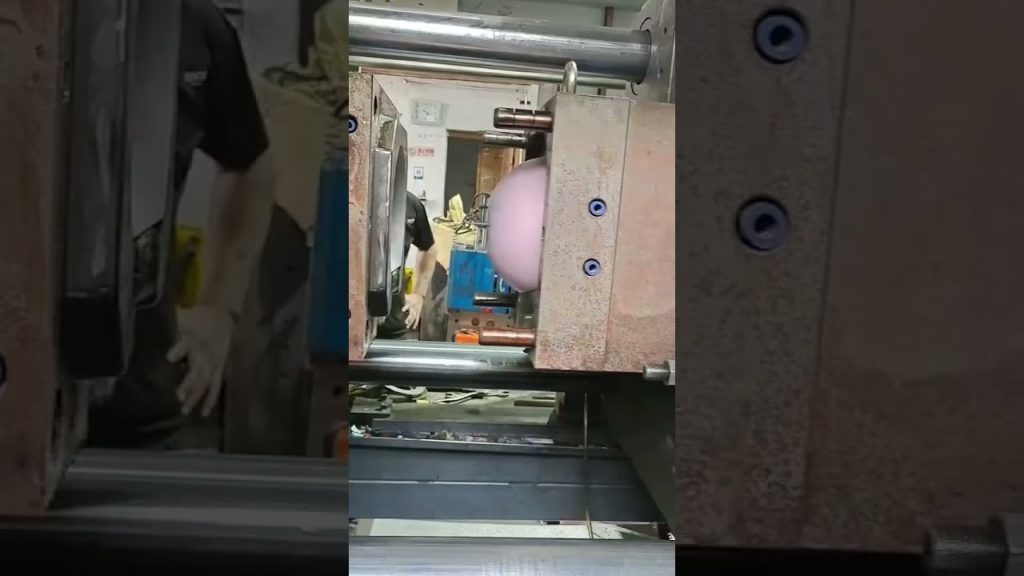

To understand the significance of industrial plastic injection machines, it is crucial to grasp their basic functioning. These machines are designed to melt plastic materials and inject them into molds to create a wide range of plastic products, including bowls. With precise control over temperature, pressure, and speed, these machines ensure the production of high-quality plastic products with consistent results.

II. Customized Injection Molds for Plastic Bowl Making

Creating plastic bowls with intricate designs and specific dimensions requires the use of customized injection molds. These molds are carefully designed and manufactured to match the desired bowl shape and size. By utilizing advanced CAD/CAM software and CNC machining processes, intricate details and complex geometries can be achieved, resulting in visually appealing and functional plastic bowls.

III. Testing and Quality Assurance in Plastic Injection Molding

To guarantee the reliability and durability of plastic bowls produced through injection molding, rigorous testing and quality assurance protocols are implemented. These processes involve inspecting the molded products for any defects, ensuring the right material composition, and conducting performance tests under various conditions. Industrial plastic injection machines offer the flexibility to alter parameters during production, enabling manufacturers to fine-tune the process and achieve optimal results.

IV. Advantages of Industrial Plastic Injection Machines

1. Efficiency and Speed: Industrial plastic injection machines operate at high speeds, allowing for large-scale production and quick turnaround times. This efficiency helps meet market demands while reducing production costs.

2. Versatility in Material Selection: These machines can work with a wide range of plastic materials, including thermoplastics and thermosetting polymers. This versatility enables manufacturers to produce bowls with different material properties, such as heat resistance, impact resistance, or transparency.

3. Cost-Effectiveness: Industrial plastic injection machines offer significant cost advantages compared to traditional manufacturing methods. The ability to produce complex shapes with minimal material waste reduces overall production costs, making plastic injection molding a cost-effective solution.

4. Consistency and Precision: By maintaining strict control over temperature, pressure, and injection speed, industrial plastic injection machines ensure consistent and precise molding results. This consistency contributes to the production of high-quality plastic bowls that meet customer expectations.

V. The Future of Plastic Injection Molding

As technology continues to advance, the future of plastic injection molding looks promising. With the integration of automation, artificial intelligence, and robotics, manufacturers can expect increased productivity, reduced downtime, and enhanced product customization. The continuous development of eco-friendly materials and sustainable manufacturing processes also paves the way for a greener future in plastic injection molding.

Conclusion:

Industrial plastic injection machines have transformed the manufacturing landscape, particularly in the production of plastic bowls through customized injection molds. With their efficiency, versatility, and cost-effectiveness, these machines have become indispensable tools for manufacturers seeking high-quality plastic products. As technology evolves, we can anticipate further advancements in plastic injection molding, opening new possibilities for innovation and sustainability.

Check out our leading manufacturer for a professional coil packing solution here: [insert manufacturer’s name or website]. Plastic Injection Machine

“Efficient Customized Injection Molding Solutions for Plastic Bowl Production: From Mold Design to Testing and Industrial Machinery”