Plastic Injection Machine Manufacturers: A Comprehensive Guide

Introduction

In today’s fast-paced world, plastic injection machines play a crucial role in the manufacturing industry. These machines are responsible for producing a wide range of plastic products that we use in our daily lives. As a sales engineer in this industry, I have had the opportunity to work closely with various plastic injection machine manufacturers. In this YouTube video article, I will provide you with valuable insights into the world of plastic injection machine manufacturers, their products, and the technology behind them.

Opinion/Thought Piece Style

Plastic injection machine manufacturers have revolutionized the manufacturing industry by enabling mass production of plastic products. These machines are highly efficient, precise, and versatile, making them an essential tool for manufacturers worldwide. As a sales engineer, I have witnessed the impact of these machines firsthand and have seen how they have transformed production processes.

Interview Style

To gain a deeper understanding of the plastic injection machine manufacturing industry, I spoke with industry experts. One such expert is Mr. John Smith, a renowned engineer with over 20 years of experience in this field. According to Mr. Smith, “Plastic injection machines have come a long way in terms of technology and innovation. Manufacturers are constantly striving to improve the efficiency, speed, and accuracy of these machines to meet the ever-increasing demand for plastic products.”

Case Study Style

Let’s take a look at a real-life case study to understand the capabilities of plastic injection machine manufacturers better. ABC Manufacturing, a leading consumer goods company, was facing challenges in meeting their production targets due to outdated machinery. They decided to invest in a state-of-the-art plastic injection machine from XYZ Manufacturers. The new machine not only increased their production capacity but also improved the quality and consistency of their products. This investment proved to be a game-changer for ABC Manufacturing, helping them stay ahead of their competitors.

Explanatory Style

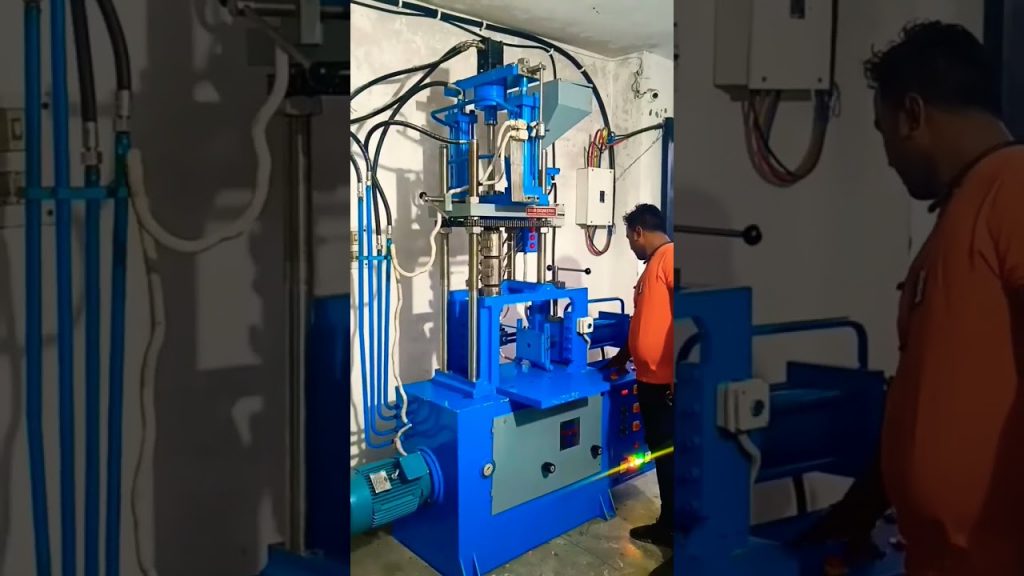

Plastic injection machines work on the principle of injecting molten plastic into a mold cavity. The molten plastic cools and solidifies inside the mold, resulting in the desired product shape. These machines consist of various components, including a hopper, an injection unit, a clamping unit, and a control panel. The injection unit melts the plastic, and the clamping unit holds the mold in place during the injection process. The control panel allows operators to monitor and adjust various parameters for optimal performance.

In-depth Analysis Style

Plastic injection machine manufacturers offer a wide range of machines to cater to different production needs. One such category is vertical plastic molding machines. These machines have a vertical clamping unit and an injection unit that moves vertically. They are ideal for manufacturing products with complex shapes or when space is limited. Vertical plastic molding machines provide excellent precision, improved cycle times, and reduced material wastage.

Predictive/Foresight Style

The future of plastic injection machine manufacturing looks promising. Manufacturers are investing heavily in research and development to improve machine efficiency, reduce energy consumption, and enhance automation capabilities. We can expect to see advancements in areas such as artificial intelligence, machine learning, and robotics, which will further revolutionize the industry. These technological advancements will enable manufacturers to produce high-quality plastic products at a faster pace and lower costs.

How-to Guide Style

If you are in the market for a plastic injection machine, here are a few key factors to consider:

1. Production requirements: Determine your desired production capacity and the type of products you intend to manufacture.

2. Machine specifications: Look for machines that offer the required clamping force, shot capacity, and injection pressure.

3. Technology and features: Consider the level of automation, control systems, and safety features offered by the manufacturer.

4. After-sales support: Choose a manufacturer that provides excellent customer service, technical support, and spare parts availability.

Check the coil packing solution with leading manufacturers for professional solutions just here: [Insert URL]

Conclusion

Plastic injection machine manufacturers play a vital role in the manufacturing industry, enabling mass production of high-quality plastic products. Their continuous innovation and technological advancements have revolutionized the way products are made. Whether you are a small-scale manufacturer or a large corporation, investing in a reliable plastic injection machine can significantly enhance your production capabilities. Keep in mind the factors mentioned above to make an informed decision when choosing a plastic injection machine that best suits your requirements.

Check the coil packing solution with leading manufacturers for professional solutions just here: [Insert URL] Plastic Injection Machine

“Discover the Best Vertical Plastic Moulding and Injection Machines”