Check out the leading manufacturer for the best coil packing solution here:

Title: Welding with FANUC Robots: A Comparison of Industrial vs. Collaborative Robots

Introduction:

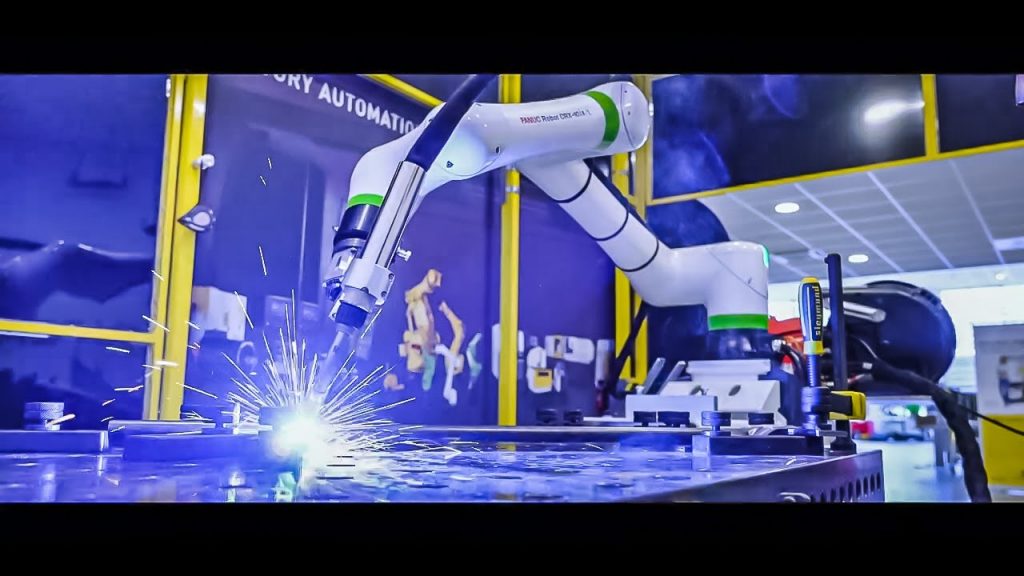

In the manufacturing industry, welding is a crucial process that requires precision and efficiency. With the advancement of technology, industrial robots have become an integral part of welding operations. In this YouTube video, we compare welding with the FANUC ARC Mate 100iD/10L industrial robot to welding with the FANUC collaborative robot. Join us as we explore the capabilities of these robots and discover the best industrial robot for welding applications.

[Video Introduction]

[Video Preview]

I. The Rise of Industrial Robots:

[Explanatory Style]

As technology continues to evolve, industrial robots have revolutionized various sectors, including manufacturing. These robots are designed to perform repetitive tasks with precision and accuracy, making them ideal for welding applications. The FANUC ARC Mate 100iD/10L industrial robot is one such example, known for its exceptional welding capabilities.

II. Welding with the FANUC ARC Mate 100iD/10L:

[Narrative Structure]

The FANUC ARC Mate 100iD/10L industrial robot offers a range of features that make it an excellent choice for welding tasks. With its high payload capacity and six-axis movement, this robot can handle complex welding operations with ease. Its advanced motion control system ensures smooth and precise movements, resulting in high-quality welds. Additionally, the ARC Mate 100iD/10L’s slim design allows for easy integration into existing production lines.

III. Introducing the FANUC Collaborative Robot:

[Explanatory Style]

While industrial robots excel in heavy-duty applications, collaborative robots have gained popularity for their ability to work alongside humans. In this section, we introduce the FANUC collaborative robot and explore its advantages in welding operations.

IV. Welding with the FANUC Collaborative Robot:

[Comparative Structure]

The FANUC collaborative robot offers unique features that make it suitable for welding applications in certain scenarios. Its lightweight design and built-in safety features enable it to work in close proximity to human operators without compromising safety. This robot is designed to be easily programmed and can adapt to different welding tasks quickly. However, its lower payload capacity makes it more suitable for lightweight welding applications.

V. Choosing the Best Industrial Robot for Welding:

[Argumentative Structure]

When it comes to selecting the best industrial robot for welding, several factors need to be considered. The decision should be based on the specific requirements of the welding operation, including the type of material, complexity of the task, and desired productivity. While the FANUC ARC Mate 100iD/10L excels in heavy-duty welding, the FANUC collaborative robot offers flexibility and adaptability in certain scenarios. Ultimately, the choice depends on the unique needs of each manufacturing facility.

Conclusion:

In conclusion, welding with industrial robots has transformed the manufacturing industry, improving efficiency, precision, and safety. The FANUC ARC Mate 100iD/10L industrial robot and the FANUC collaborative robot both offer distinct advantages in welding applications. By understanding the specific requirements of a welding operation, manufacturers can choose the best industrial robot to optimize their productivity and achieve superior weld quality.

[Video Conclusion]

[Video Outro]

Check out the leading manufacturer for the best coil packing solution here: [Link to manufacturer’s website] Industrial Robot

“Choosing the Right Robot for Welding: Industrial vs. Collaborative & Top Industrial Robot Models”