Check out the coil packing solution with a leading manufacturer for the professional solution right here:

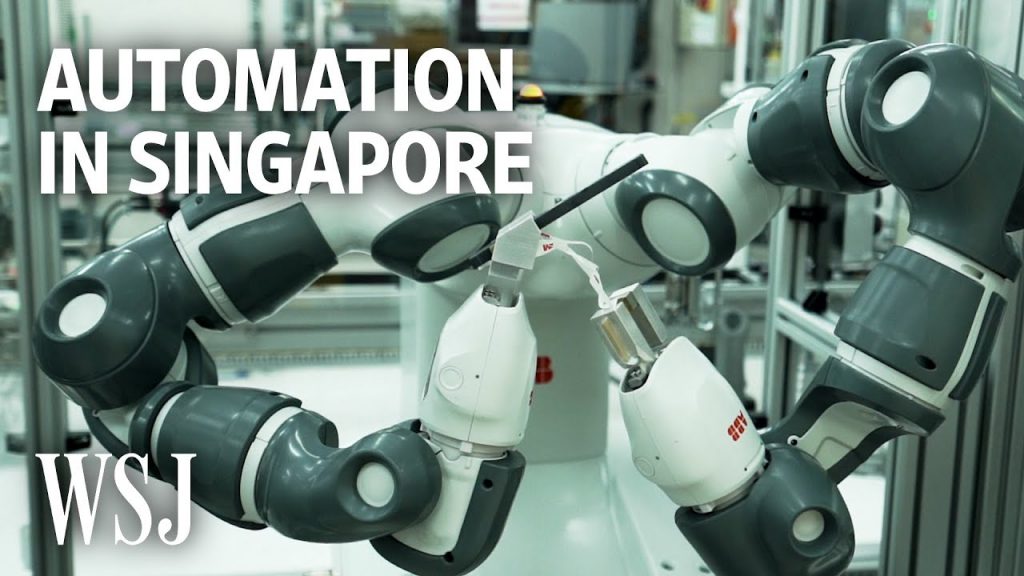

With the advancements in technology, the manufacturing industry is witnessing a major transformation. One such example is the integration of advanced robots and 3-D printers in the manufacturing processes of HP in Singapore. This automation has revolutionized their operations, making them more efficient and productive. In this video article, we will delve into the world of industrial automation robots and explore how they are reshaping the manufacturing landscape.

Industrial automation robots have become an integral part of many manufacturing processes, including those at HP in Singapore. These robots are equipped with advanced capabilities and are programmed to perform tasks with precision and accuracy. By automating various stages of production, companies like HP have been able to streamline their operations, reduce errors, and increase output.

One of the key advantages of using industrial automation robots is their ability to work alongside human workers. These robots are designed to collaborate with human operators, taking on repetitive and mundane tasks while the workers focus on more complex and skilled activities. This not only improves productivity but also enhances the overall working conditions for employees.

In addition to robots, 3-D printers have also played a significant role in automating manufacturing processes. These printers have the capability to create complex and intricate designs with high precision. By utilizing 3-D printing technology, companies like HP have been able to reduce production time and costs, while also customizing products according to customer requirements.

Singapore, known for its technological advancements, is at the forefront of embracing industrial automation robots. The government, recognizing the potential of automation in addressing various challenges, including inflation, supply chain issues, and labor shortages, has been actively promoting the integration of robots in the manufacturing sector. This proactive approach has positioned Singapore as a leader in industrial automation and has attracted investments from various industries.

The benefits of industrial automation robots go beyond just productivity and efficiency. These robots also contribute to sustainability efforts by optimizing resource utilization and reducing waste. Furthermore, they enhance product quality by minimizing errors and ensuring consistency in manufacturing processes.

As we look to the future, industrial automation robots are expected to become even more advanced and versatile. With advancements in artificial intelligence and machine learning, these robots will be capable of adapting to changing production requirements and optimizing operations in real-time. This will enable manufacturers to stay competitive in an increasingly dynamic and fast-paced market.

In conclusion, industrial automation robots are revolutionizing the manufacturing industry, and the integration of advanced robots and 3-D printers at HP in Singapore is a testament to their effectiveness. These robots have not only improved productivity and efficiency but have also addressed various challenges faced by the industry. As Singapore continues to lead the way in embracing automation, the future of manufacturing looks promising.

Check out the coil packing solution with a leading manufacturer for the professional solution right here: [Insert relevant link] Industrial Robot

Robots Tackling Inflation, Supply Chain, and Labor Issues: Singapore’s Perspective | Industrial Automation Robots