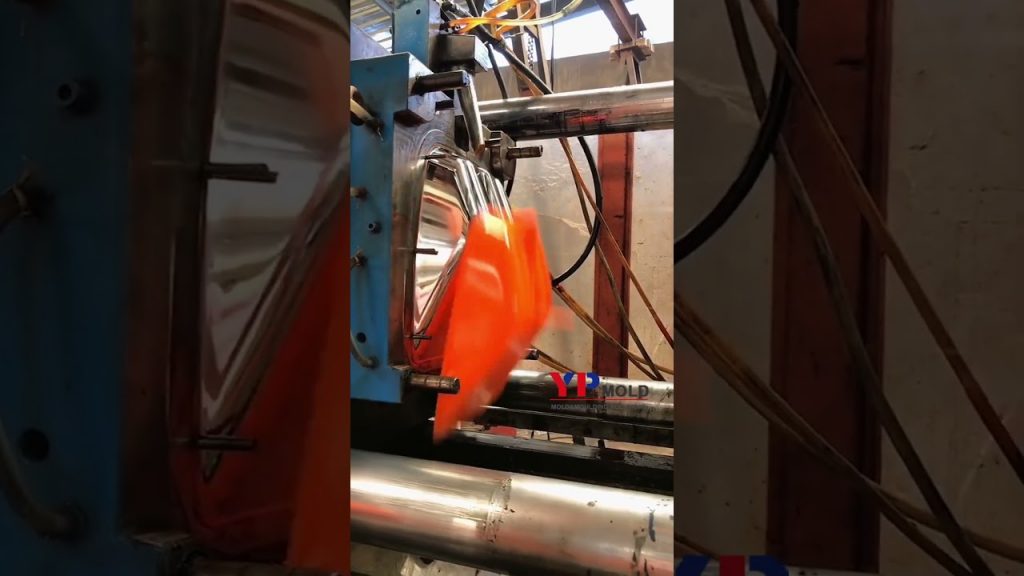

Plastic Injection Machine Price: A Comprehensive Guide to Calculating the Cost of Injection Mold Tooling

Introduction:

If you are in the market for a plastic injection machine, understanding the price factors and how to calculate the cost of injection mold tooling is crucial. In this article, we will delve into the various aspects that determine the price of a plastic injection machine, providing you with the necessary information to make an informed purchasing decision. So, let’s dive right in!

Plastic Injection Machine Price Factors:

1. Machine Size and Capacity:

The size and capacity of a plastic injection machine play a significant role in determining its price. Larger machines capable of handling higher volumes of production generally come at a higher price point. The machine’s tonnage, which represents its clamping force, is a crucial factor to consider when determining the price.

2. Machine Features and Technology:

Advanced features and technology integrated into a plastic injection machine can significantly impact its price. Machines equipped with automation, precision control systems, and advanced software functionalities tend to be priced higher. These features enhance the efficiency, accuracy, and overall performance of the machine.

3. Brand and Reputation:

The reputation and brand of the manufacturer also influence the price of a plastic injection machine. Well-established brands with a proven track record of producing high-quality machines often come at a premium price. However, opting for a reputable brand ensures reliability, durability, and access to reliable customer support.

4. Material Compatibility:

Different plastic materials require specific machine capabilities and components. Machines designed to handle a wide range of materials, including specialized resins or high-performance plastics, may have a higher price tag. It is important to consider the material compatibility of the machine based on your specific production requirements.

Calculating the Cost of Injection Mold Tooling:

Injection mold tooling is an essential component of the plastic injection process. The cost of tooling plays a significant role in the overall price of the plastic injection machine. Here’s a step-by-step guide to calculating the cost of injection mold tooling:

1. Determine the mold design complexity:

The complexity of the mold design impacts the cost of tooling. Intricate designs with multiple cavities, slides, or undercuts require more intricate tooling and, therefore, incur higher costs.

2. Calculate the total number of cavities:

The number of cavities in the mold directly affects the production output. Higher cavity counts increase the machine’s productivity but also add to the tooling cost.

3. Estimate the mold base size:

The size and complexity of the mold base have a direct correlation with the tooling cost. Larger and more complex mold bases require additional machining and, subsequently, increase the cost.

4. Consider the mold material:

The type of material used for the mold impacts tooling cost. Commonly used materials include steel and aluminum, with steel molds being more expensive but offering superior durability and longevity.

5. Account for additional features:

Additional features such as slides, inserts, or lifters add complexity to the mold design and increase the tooling cost.

By considering these factors and working closely with mold manufacturers, you can accurately calculate the cost of injection mold tooling.

Conclusion:

In conclusion, understanding the various factors that determine the price of a plastic injection machine is crucial for making an informed purchasing decision. Factors such as machine size, features, brand reputation, and material compatibility all contribute to the overall price. Additionally, calculating the cost of injection mold tooling is essential to accurately determine the complete investment required. By considering these aspects and seeking professional guidance, you can ensure that your plastic injection machine investment aligns with your production needs.

Check the coil packing solution with a leading manufacturer for the professional solution just here: [Insert Call-to-Action Statement] Plastic Injection Machine

“Mastering Injection Molding Costs: Unveiling the Process and Pricing Factors”