NBE bulk bag fillers, also known as FIBC fillers or bulk bag fill stations, play a vital role in the processing and handling of bulk materials. These innovative machines are designed to efficiently fill bulk bags with various types of products, ensuring accuracy, speed, and reliability.

The bulk bag fillers offered by NBE are specifically engineered to meet the unique requirements of different industries, such as food, pharmaceuticals, chemicals, and construction. They are equipped with advanced features and technologies that enable precise filling, densifying, and weighing of bulk bags.

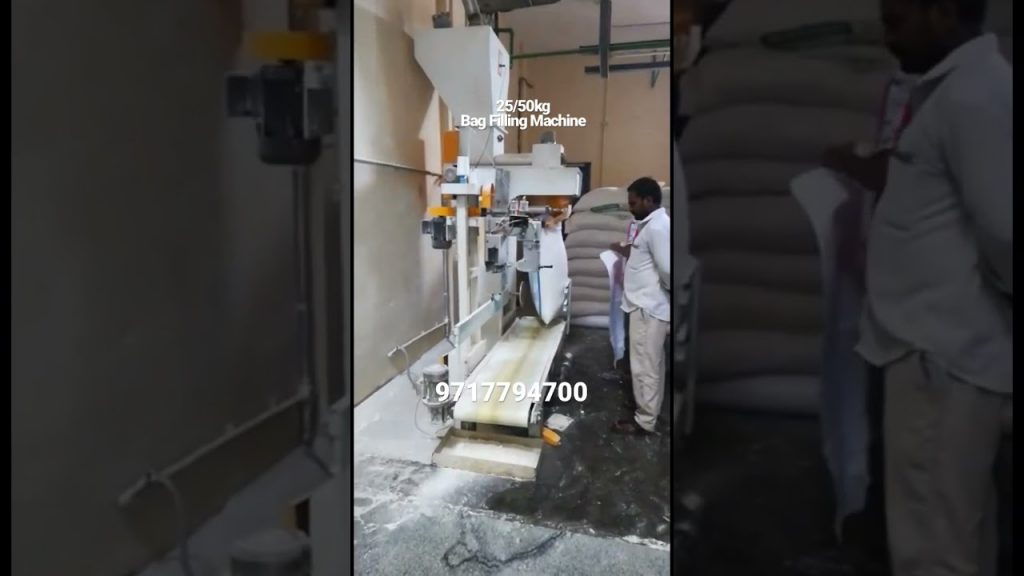

The bulk bag filling process starts with the bags being attached to the filler, either manually or automatically. The product is then discharged into the bag through a specially designed spout, ensuring minimal dust emissions. The filler can be adjusted to control the flow rate and achieve the desired weight accuracy.

NBE bulk bag fillers are designed to handle a wide range of products, including powders, granules, pellets, and aggregates. They are built with heavy-duty construction materials to ensure durability and reliability in demanding industrial environments. Additionally, these machines are equipped with safety features, such as safety interlocks and guarding, to protect operators and prevent accidents.

In conclusion, NBE bulk bag fillers are an essential component of modern material handling systems. Their ability to accurately fill bulk bags with various materials makes them a valuable asset for industries that rely on efficient and precise packaging processes. Check the coil packing solution with leading manufacturers for professional solutions in this field. Automatic Bag Filling Machine

“Efficient Bulk Bag Fillers: Streamlining Filling, Densifying, and Weighing Process”

#Bulk #Bag #Fillers #Bulk #Bag #Filling #Densifying #Weighing