How to fill a Fluid-Bag container using a Filling Station

Fluid-Bag containers are a convenient and efficient way to transport and store liquids. Filling these containers at a Fluid-Bag Filling Station ensures a safe and proper filling process. Here is a step-by-step guide on how to fill a Fluid-Bag container using a Filling Station:

1. Prepare the Fluid-Bag Filling Station: Ensure that the Filling Station is clean and free from any contaminants. Check that the necessary equipment, such as pumps and hoses, are in good working condition.

2. Position the Fluid-Bag container: Place the empty Fluid-Bag container securely in the Filling Station. Make sure it is properly aligned and stable.

3. Connect the filling equipment: Attach the filling hose to the designated outlet on the Filling Station. Ensure a secure connection to prevent any leakage during the filling process.

4. Start the filling process: Activate the pump and allow the liquid to flow into the Fluid-Bag container. Monitor the filling process carefully to prevent overfilling or spillage.

5. Monitor the filling level: Keep an eye on the filling level indicator on the Fluid-Bag container. Once the container is filled to the desired level, stop the filling process.

6. Disconnect the filling equipment: Shut off the pump and disconnect the filling hose from the Filling Station. Ensure that any remaining liquid in the hose is properly drained.

7. Securely close the Fluid-Bag container: Seal the Fluid-Bag container tightly using the provided closure system. This will ensure that the liquid remains safely contained during transportation.

By following these steps, you can successfully fill a Fluid-Bag container using a Filling Station. It is important to always prioritize safety and accuracy during the filling process.

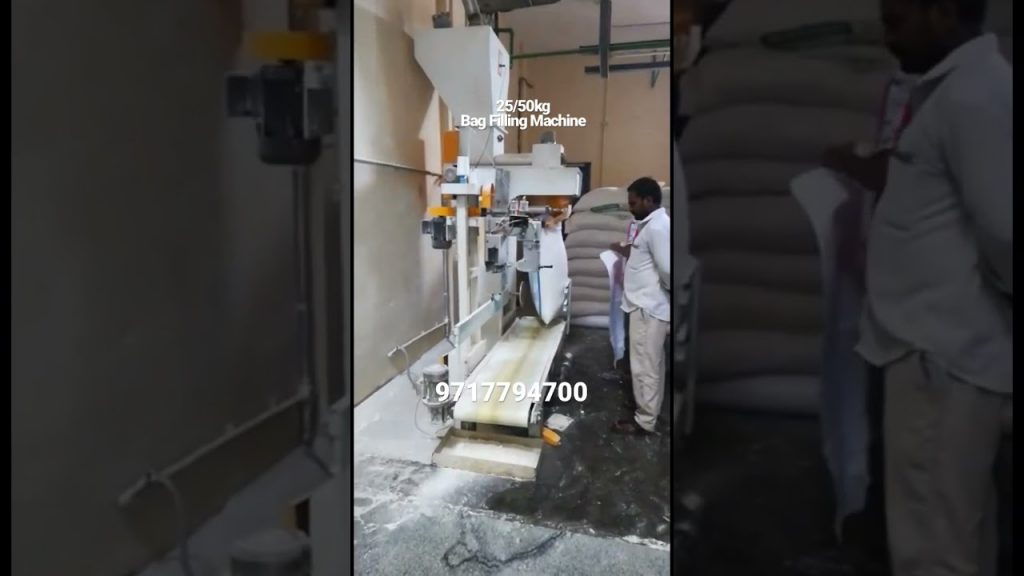

Check the coil packing solution with a leading manufacturer for a professional solution. Automatic Bag Filling Machine

“Efficient and Convenient Solution for Bulk Liquid Packaging”

#FluidBag #Filling #Station