Title: Efficient and Versatile Automatic Box Packing Line and Medicine Bottle Sorting Machine

Description:

Welcome to our video showcasing the cutting-edge technology of the Automatic Box Packing Line and Medicine Bottle Sorting Machine. As packaging machine experts at Y-pack packaging technology Co., Ltd., we are excited to present this innovative solution that caters to various packaging needs, be it for boxes or bags.

Introduction:

In this video, we will dive into the world of packaging technology and explore the remarkable features and capabilities of our Automatic Box Packing Line and Medicine Bottle Sorting Machine. Whether you are a packaging professional or simply curious about the latest advancements in this field, this video is a must-watch.

Video Content:

1. Overview of the Automatic Box Packing Line:

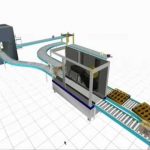

– Our Automatic Box Packing Line is designed to streamline and automate the packaging process, increasing efficiency and reducing human error.

– This state-of-the-art system can handle various box sizes and shapes, ensuring precise and secure packaging for different products.

– With its advanced technology, the machine optimizes space utilization, minimizing material waste and reducing packaging costs.

2. Medicine Bottle Sorting and Box Packing:

– Our cutting-edge machine excels in sorting and packing medicine bottles with utmost accuracy and speed.

– It utilizes advanced optical sensors and sorting mechanisms to ensure that each bottle is correctly placed and securely packed.

– The system can handle a wide range of bottle sizes and shapes, making it suitable for pharmaceutical companies of all scales.

3. Box Erecting and Cartoning:

– The Automatic Box Packing Line also includes a box erecting and cartoning feature, eliminating the need for manual box assembly.

– With its precise folding and sealing capabilities, the machine ensures that each box is perfectly formed and ready for packaging.

– This feature significantly reduces labor costs and enhances overall production efficiency.

Call to Action:

If you found this video informative and intriguing, we encourage you to hit the like button, subscribe to our channel, and share this video with your colleagues and friends. Stay updated with the latest advancements in packaging technology by joining our community.

Additional Tags and Keywords:

#AutomaticBoxPacking #MedicineBottleSorting #BoxErecting #Cartoning #PackagingMachine #YpackTechnology #EfficientPackaging #StreamlinedAutomation

Hashtags:

#AutomaticBoxPacking #MedicineBottleSorting #BoxErecting #Cartoning #PackagingTechnology #YpackTechnology #EfficientPackaging #Automation

Title: Automated Box Erecting and Cartoning System for Medicine Bottle Sorting and Packing Machine

Introduction:

The box erecting and cartoning process is a crucial step in the medicine bottle sorting and packing machine. It involves automatically setting up boxes and efficiently placing the sorted medicine bottles into the boxes. This paper presents a tilter design for an automated box erecting and cartoning system, aiming to improve the efficiency and accuracy of the overall process.

I. System Overview:

1. Box Erecting Mechanism:

– Utilizes a robotic arm with suction cups to pick up flat boxes from a stack and erect them into a ready-to-use position.

– Incorporates sensors and vision systems to ensure proper box alignment and integrity.

2. Cartoning Mechanism:

– Consists of a conveyor belt that transports the bottles towards the cartoning area.

– Utilizes a robotic arm with a gripper to pick up the bottles and place them into the erected boxes.

– Implements a vision system to accurately detect and position the bottles within the boxes.

II. Tilter Design:

1. Purpose:

– The tilter is responsible for tilting the erected boxes to a specific angle, allowing easy insertion of medicine bottles.

– It ensures that the bottles are properly aligned and positioned inside the boxes, minimizing the risk of damage during transportation.

2. Mechanical Components:

– The tilter consists of a motorized platform with adjustable tilting angles.

– It is equipped with sensors to detect the presence and position of the boxes, ensuring precise tilting.

3. Control System:

– The tilter is controlled by a programmable logic controller (PLC) that receives signals from the main sorting and packing machine.

– The PLC coordinates the tilter’s movement with the box erecting and cartoning mechanisms, ensuring synchronized operations.

III. Operation Flow:

1. Box Erecting:

– The box erecting mechanism picks up a flat box using suction cups and positions it in the tilter.

– The tilter tilts the box to the desired angle, ensuring easy insertion of medicine bottles.

2. Cartoning:

– The cartoning mechanism transports the sorted medicine bottles towards the tilter.

– The tilter receives signals from the vision system to detect the presence and position of the bottles.

– Once the bottles are detected, the tilter tilts the box back to a horizontal position.

– The cartoning mechanism uses a robotic arm to pick up the bottles and place them accurately inside the box.

IV. Benefits:

1. Increased Efficiency:

– The tilter streamlines the box erecting and cartoning process, reducing manual labor and increasing overall productivity.

– It enables faster and more accurate insertion of medicine bottles into the boxes.

2. Improved Product Quality:

– The tilter ensures precise alignment and positioning of medicine bottles inside the boxes, reducing the risk of damage during transit.

3. Flexibility:

– The tilter’s adjustable tilting angles allow customization to accommodate different box sizes and bottle orientations.

Conclusion:

The tilter design for the automated box erecting and cartoning system enhances the efficiency and accuracy of the medicine bottle sorting and packing machine. It enables seamless integration of the box erecting, tilting, and cartoning processes, resulting in improved productivity and product quality. coil packing line

#Medicine #Bottle #Sorting #Box #Packing #Machine #③Box #Erecting #Cartoning