Check out our website for more information and to find the perfect solution for your coil packing needs.”

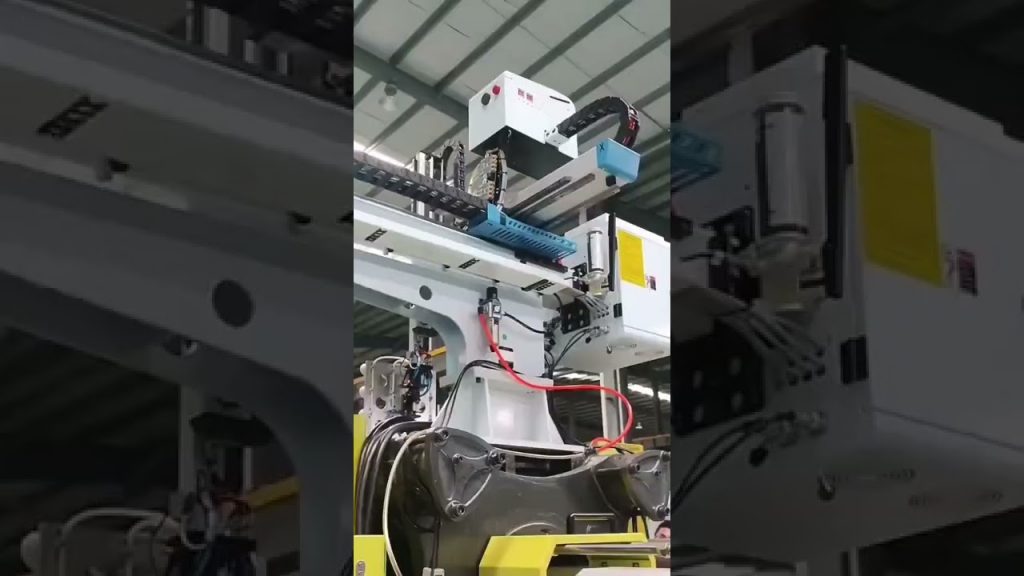

Title: PowerjetGroup PE Plastic Caps Production with Powerjet KII330: Boosting Efficiency with High-Speed Plastic Injection Machines

Introduction:

In the world of plastic manufacturing, efficiency and speed are key factors in staying ahead of the competition. PowerjetGroup, a leading provider of high-quality plastic injection machines, introduces the Powerjet KII330, a high-speed plastic injection machine that revolutionizes the production of PE plastic caps. In this article, we will explore the capabilities of this cutting-edge machine and its impact on the industry.

Explanatory Style:

Powerjet KII330: Unleashing the Potential of High-Speed Plastic Injection Machines

Plastic caps are an essential component in various industries, such as beverage, pharmaceutical, and cosmetics. The demand for these caps is ever-increasing, necessitating the need for efficient and reliable production methods. PowerjetGroup, with its expertise in plastic injection machines, has developed the Powerjet KII330 to meet these demands.

The Powerjet KII330 is a high-speed plastic injection machine specifically designed for the production of PE plastic caps. With its advanced technology and features, this machine takes the production process to the next level, delivering exceptional results in terms of speed, precision, and quality.

Unmatched Speed and Efficiency:

One of the standout features of the Powerjet KII330 is its impressive speed. Capable of operating at high speeds, this machine ensures rapid production cycles, resulting in increased output and reduced production time. By utilizing the latest technology and a robust injection system, the Powerjet KII330 delivers consistent and precise injection molding, enabling a seamless production process.

Precision and Quality:

The Powerjet KII330 prioritizes precision and quality in every step of the production process. Equipped with advanced control systems and sensors, the machine ensures accurate and uniform injection molding, minimizing defects and ensuring the highest level of quality in the final product. This not only enhances customer satisfaction but also reduces wastage and optimizes resource utilization.

Enhanced Productivity:

By harnessing the power of high-speed plastic injection technology, the Powerjet KII330 significantly enhances productivity. The machine’s ability to produce a large number of PE plastic caps in a short period of time translates into increased production capacity and greater efficiency. This allows businesses to meet growing demands, expand their market reach, and improve profitability.

Cost-Effective Solution:

In addition to its impressive speed and efficiency, the Powerjet KII330 offers a cost-effective solution for plastic cap production. By streamlining the production process and minimizing material waste, this machine helps businesses reduce costs and maximize profitability. Furthermore, its durability and low maintenance requirements ensure long-term savings, making it a smart investment for any plastic manufacturing operation.

Conclusion:

The Powerjet KII330 from PowerjetGroup represents a game-changing solution for the production of PE plastic caps. Its high-speed capabilities, precision molding, enhanced productivity, and cost-effectiveness make it a top choice for businesses looking to stay ahead in the competitive plastic manufacturing industry.

Whether you are a small-scale manufacturer or a large-scale production facility, the Powerjet KII330 offers the perfect solution to boost your efficiency and meet the growing demands of the market. Invest in this cutting-edge machine and experience the benefits of high-speed plastic injection technology firsthand.

Check out our website for more information and to find the perfect solution for your plastic cap production needs.” Plastic Injection Machine

“Efficient Testing of High-Speed Injection Molding Machines for PE Plastic Caps”