What Are the Long-Term Cost Implications of Coil Upender Energy Recovery Systems?

Coil upender energy recovery systems promise efficient coil handling, however, evaluating long-term costs is critical. Beyond initial investment, factors like energy savings, maintenance, and potential government incentives impact overall lifecycle expenses. A comprehensive cost-benefit analysis is essential for informed decision-making.

The long-term cost implications of coil upender energy recovery systems involve reduced energy consumption, minimized operational costs, decreased maintenance, and eligibility for government incentives. These factors, offset the initial investment, making them a cost-effective and sustainable solution.

Understanding the long-term financial impact requires a deep dive into these systems' operational dynamics. Let's explore how these advanced systems can transform coil handling while delivering substantial cost advantages over their lifespan.

The Core Principles of Coil Upender Energy Recovery Systems

Coil upender energy recovery systems enhance safety and efficiency in coil handling. Understanding the systems requires examining their components, energy regeneration, and how these aspects contribute to reducing long-term costs.

Coil upender energy recovery systems work by capturing and reusing the energy generated during the coil tilting process. They reduce energy consumption and lower operational costs. This is achieved through mechanisms that convert kinetic energy into electrical energy, minimizing energy wastage and maximizing overall efficiency.

Diving Deep into the Mechanics

The primary goal is to understand each component and the operational factors involved in these systems:

System Components:

Coil upender energy recovery systems typically consist of several key components:

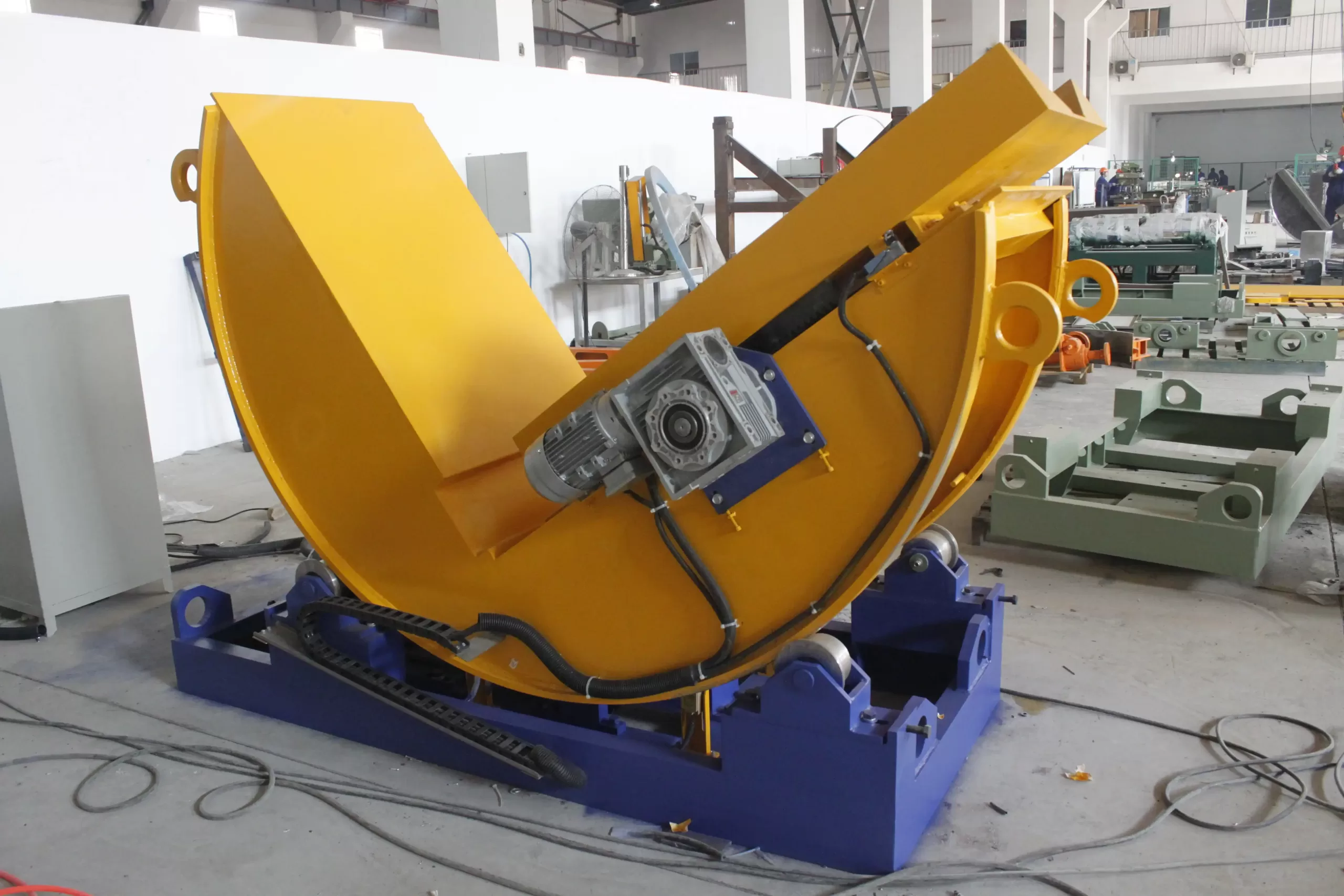

- Coil Upender: The primary mechanism for lifting and tilting heavy metal coils.

- Energy Regeneration Unit: Captures and converts energy generated during the upending process.

- Control System: Manages the energy capture and release, optimizing efficiency.

- Energy Storage: Stores converted energy for later use or feedback into the grid.

Energy Regeneration Methods:

The regeneration process employs various methods to harness energy:

- Regenerative Braking: Converts kinetic energy from the upender's movements into electrical energy.

- Hydraulic Accumulators: Store hydraulic energy for release during peak demand.

- Flywheel Energy Storage: Utilizes a rotating mass to store and release kinetic energy.

Operational Factors

Several operational aspects affect the efficiency and cost savings:

- Coil Weight and Size: Heavier coils generate more regenerative energy.

- Upender Cycle Frequency: More frequent cycles increase energy capture potential.

- System Load Management: Optimizing energy use based on demand reduces wastage.

Understanding the Long-Term Cost Implications

To fully appreciate the cost benefits, consider the lifecycle costs (LCC) over a typical 30-year period:

| Cost Component | Traditional System | Energy Recovery System |

|---|---|---|

| Initial Investment | \$50,000 | \$75,000 |

| Energy Consumption (Annual) | \$10,000 | \$4,000 |

| Maintenance (Annual) | \$2,000 | \$1,500 |

| Replacement Parts | \$5,000 | \$3,000 |

| Government Incentives | \$0 | \$5,000 (one-time) |

| Total Cost (30 years) | \$375,000 | \$202,000 |

As evident, while the initial investment for an energy recovery system is higher, the long-term savings on energy consumption and maintenance significantly reduce overall costs. Government incentives further sweeten the deal, making it a financially sensible choice. This data shows that in the long run, the costs associated with energy consumption from conventional Coil Upender systems is significantly higher than it is when implementing an Energy Recovery System.

Examining Direct and Indirect Cost Savings

Coil upender energy recovery systems go beyond initial energy savings. They offer a spectrum of direct and indirect benefits that contribute to long-term cost reduction.

Coil upender energy recovery systems lower direct costs by decreasing energy consumption and reducing maintenance needs. Indirect savings come from extended equipment lifespan, improved operational efficiency, enhanced safety, and potential eligibility for environmental incentives.

Quantifying the Financial Advantages

Let's delve into the specifics:

Direct Cost Savings

- Energy Consumption Reduction: Energy recovery minimizes electricity use, substantially lowering energy bills.

- Maintenance Reduction: Advanced design and lower stress on components reduce wear and tear.

- Reduced Downtime: Greater reliability leads to fewer breakdowns and increased uptime.

Indirect Cost Savings

- Extended Equipment Lifespan: Lower operational stress prolongs the life of machinery, reducing replacement costs.

- Enhanced Operational Efficiency: Improved material flow and precision handling boost overall productivity.

- Improved Safety: Safer coil handling minimizes the risk of accidents, lowering insurance premiums and potential liability costs.

- Government Incentives and Tax Credits: Eligibility for green initiatives and tax benefits.

Deep Dive into ROI

To accurately assess the financial benefits, a thorough cost-benefit analysis is essential. Consider these variables:

- Energy Costs: Fluctuations in energy prices can significantly affect savings.

- Maintenance Schedules: Predictive maintenance can further reduce unexpected downtime.

- Operational Volume: Higher throughput amplifies the savings generated by energy recovery.

- System Scalability: The system's ability to handle increasing production demands without compromising efficiency.

Consider a scenario where a manufacturing facility implements a coil upender energy recovery system. The initial investment is \$75,000. Here’s a cost-benefit breakdown:

- Year 1:

- Energy savings: \$4,000

- Maintenance savings: \$500

- Government incentive: \$5,000

- Total savings: \$9,500

- Year 5:

- Cumulative energy savings: \$20,000

- Cumulative maintenance savings: \$2,500

- Total cumulative savings: \$22,500

- Year 10:

- Cumulative energy savings: \$40,000

- Cumulative maintenance savings: \$5,000

- Total cumulative savings: \$45,000

Over 10 years, the system generates significant savings. By year 7, the initial investment is fully recovered, illustrating the financial viability and sustainability of the system.

Evaluating Long-Term Sustainability and Environmental Impact

Beyond immediate financial benefits, consider the broader sustainability and environmental impact. Energy recovery systems align with corporate social responsibility (CSR) goals.

Long-term sustainability and positive environmental impact from coil upender energy recovery systems stem from reduced carbon emissions, optimized resource use, and minimized waste. These contribute to environmental stewardship and enhanced corporate social responsibility.

-### The Ripple Effect of Sustainable Practices:

-

Reduced Carbon Footprint:

- Decreasing energy consumption directly lowers carbon emissions.

- Using renewable energy sources to power these systems further reduces environmental impact.

-

Optimized Resource Use:

- Efficient energy use conserves valuable resources.

- Extended equipment lifespan reduces the need for frequent replacements.

-

Waste Minimization:

- Lower maintenance reduces waste generation.

- Recyclable components and eco-friendly materials support circular economy principles.

For organizations committed to reducing their environmental footprint, the long-term benefits can be substantial:

| Sustainability Metric | Traditional System | Energy Recovery System |

|---|---|---|

| Annual Carbon Emissions | 50 tons | 20 tons |

| Resource Depletion | High | Medium |

| Waste Generation | Medium | Low |

| Environmental Compliance | Basic | Enhanced |

The numbers show that adopting coil upender energy recovery systems leads to significant reductions in carbon emissions and enhanced environmental performance, bolstering the organization's reputation and appeal to environmentally conscious stakeholders. By leveraging coil tippers and upenders that minimize energy use, businesses demonstrate their dedication to sustainable operations.

Implementing energy recovery systems demonstrates a commitment to environmental stewardship and positions the company as a leader in sustainable engineering practices. Sustainable practices often attract environmentally conscious customers and investors, enhancing brand reputation. Compliance with stringent environmental regulations can be achieved more easily, reducing the risk of penalties and ensuring long-term operational viability. A commitment to sustainability can improve employee morale and attract top talent, fostering a culture of environmental responsibility.

Conclusion

In conclusion, the adoption of coil upender energy recovery systems presents a compelling case for long-term cost savings and enhanced sustainability. While the initial investment may be higher, the substantial reductions in energy consumption, maintenance, and downtime, coupled with government incentives, result in a financially sound and environmentally responsible investment. For companies seeking to optimize their operations while reducing their carbon footprint, coil upender energy recovery systems offer a pathway to both economic prosperity and [coil packing line]() environmental stewardship.