Navigating the market for steel coil packing machines involves evaluating key manufacturers like FHOPEPACK and SHJLPACK. Understanding the price landscape requires looking beyond the initial quote, considering factors like machine specifications, automation levels, and long-term value. This comparison aims to shed light on what influences the steel coil packing machine price offered by these two prominent suppliers for plant engineering decisions.

Determining the exact steel coil packing machine price difference between FHOPEPACK and SHJLPACK is complex, as costs depend heavily on customization, features, and coil specifications. Both manufacturers offer competitive solutions, but FHOPEPACK often emphasizes advanced automation and tailored features which may influence initial cost, while SHJLPACK leverages extensive experience and a broad product range, potentially offering varied price points across different machine tiers.

Choosing the right steel coil packing machine is a significant capital investment impacting operational efficiency, safety, and product integrity. While the upfront price is a major consideration, plant engineers must delve deeper into the offerings of manufacturers like FHOPEPACK and SHJLPACK. Evaluating machine capabilities, build quality, customization potential, and after-sales support provides a clearer picture of total cost of ownership and return on investment, guiding a decision that aligns with specific production needs and long-term strategic goals.

Understanding FHOPEPACK's Steel Coil Packing Solutions and Pricing Factors

FHOPEPACK positions itself as an innovator in the packaging machinery sector, offering specialized steel coil packing solutions. Their approach often involves integrating advanced technologies and high levels of customization, which are significant determinants of the final machine price, tailored to specific plant requirements and performance expectations.

FHOPEPACK's steel coil packing machine pricing is influenced by high levels of customization, advanced features like PLC controls (often using recognized brands like Siemens or Allen-Bradley) and specialized tension systems for optimal wrapping, and robust build quality using high-quality components. While potentially representing a higher initial investment compared to standard models, their machines like the FPS-600 steel coil wrapping machine are designed for specific performance requirements, offering long-term value through efficiency and tailored solutions. Options such as automatic material cutters, Human-Machine Interfaces (HMI), and safety interlocks further impact the final price, reflecting the specific configuration chosen by the plant engineer.

Analyzing FHOPEPACK's Machine Specifications and Value Proposition

When evaluating FHOPEPACK's offerings from a plant engineering perspective, the focus shifts to technical specifications, reliability, and the impact of features on operational efficiency and cost. Their emphasis on "excellent collections" and "high-quality brands" for main components suggests a commitment to durability and reduced downtime, factors critical in calculating the Total Cost of Ownership (TCO).

The FHOPEPACK FPS-600 model, detailed in the provided material, serves as a good example. Key features influencing its performance and price include:

- Control System: Utilization of PLC (Programmable Logic Controller) allows for precise control over the wrapping process, integration with plant control systems, and potential for future upgrades. The choice of PLC brand can impact cost and compatibility.

- Loading/Unloading: The inclusion of a trolley system simplifies coil handling, enhancing safety and reducing manual labor, contributing positively to ROI.

- Adjustability: Motorized adjustment of the ring board height accommodates varying coil Outside Diameters (OD), increasing machine flexibility. The range (e.g., 1000-1500mm OD for FPS-600) dictates the machine's applicability.

- Wrapping Material: Capability to handle multiple wrapping materials simultaneously (e.g., stretch film and paper/woven tape) offers versatility in packaging protocols.

- Tension Control: A specialized tension control system ensures consistent wrap tightness across different coil sizes, crucial for package integrity. Advanced systems offer better control but may increase cost.

- Safety Features: Incorporation of protective guards, soft start/stop functions, overload protection, electrical and mechanical limitations, and indicator alarms are essential for operator safety and regulatory compliance. Fortress interlocks are offered as an option for enhanced safety.

- Performance Metrics: Ring speed (approx. 20-60 r/min) and roller speed (approx. 3-5m/min) determine the cycle time and overall throughput. Adjustable overlapping rates (20%-90%) allow fine-tuning of material usage and protection levels.

- Construction: Features like a reinforced ring structure and Polyurethane (PU) wheels point towards durability and longevity.

- Optional Enhancements: The availability of automatic material cutters and HMI significantly boosts automation, reducing operator intervention and cycle time, but adds to the initial cost.

The following table summarizes key specifications for a representative FHOPEPACK machine (based on FPS-600 data) and highlights aspects relevant to pricing:

| Feature | Specification (FPS-600 Example) | Price Implication / Value Proposition |

|---|---|---|

| Coil Width | 200-600mm | Defines machine size and capability |

| Coil ID | 700-1100mm | Influences ring size and machine design |

| Coil OD | 1000-1500mm | Key factor in machine scale and cost |

| Coil Weight | 200-2000kg | Dictates structural robustness, motor power, roller strength |

| Control System | PLC | Standard for automation; brand/complexity affects price |

| Ring Speed | approx. 20-60r/min | Higher speed = higher throughput, potentially higher cost |

| Roller Speed | Approx 3-5m/min | Coordinated with ring speed for proper wrapping |

| Power Output | Approx. 7.5kw | Influences energy consumption (operational cost) |

| Packing Material | Stretch Film, Paper, Knit Tape | Versatility; ability to handle multiple types is a plus |

| Tension Control | Special System | Ensures quality wrap; advanced systems cost more |

| Safety Features | Guards, Soft Start/Stop, Alarms | Essential; higher levels (e.g., interlocks) add cost |

| Optional Auto Cutter | Available | Increases automation & efficiency, adds significant cost |

| Optional HMI | Available (req. for auto cutter) | Enhances user interface & control, adds cost |

| Component Quality | "High-quality brands" | Higher initial cost, potentially lower TCO via reliability |

| Customization | High | Allows tailoring but increases engineering/manufacturing cost |

For plant engineers, the value proposition of FHOPEPACK lies in potentially achieving highly specific packaging requirements through customization and advanced features, leading to optimized performance, material usage, and integration possibilities, justifying a potentially higher initial investment through long-term operational benefits.

Exploring SHJLPACK's Steel Coil Packing Portfolio and Cost Considerations

SHJLPACK enters the comparison with a notable history, claiming over 18 years of experience and a broad portfolio encompassing various coil types and related packaging machinery. This extensive experience and wide product range suggest potential economies of scale and diverse pricing structures.

SHJLPACK's steel coil packing machine price is shaped by their extensive portfolio, offering solutions from basic, cost-effective models (like the simpler GS300) to complex, fully automated packing lines integrating wrapping, strapping, and handling. Their long industry presence and large customer base (claiming 500+) may allow for competitive pricing strategies across different machine tiers. Price varies significantly based on the specific machine series (e.g., vertical GD, horizontal GW), coil handling capacity (size and weight), and the level of automation and optional functions selected, such as automatic weighing, logo tapping, or coil centering devices.

SHJLPACK's Diverse Machine Range and Service Impact on Pricing

SHJLPACK's strength appears to lie in the breadth of its offerings. Their website showcases a wide array of machines catering to different needs within the coil packaging spectrum:

- Steel Coil Machines: They offer various models specifically for steel coils, including master coil wrappers (GD2000), machines with trolleys for crane loading (GD800), horizontal wrappers (GW300), vertical wrappers (GD300), and simpler models (GS300). This variety implies solutions tailored to different throughputs, handling methods, and budget constraints. They explicitly mention lines for slitting coils, indicating specialization. You can explore their Steel coil wrapping machine range for more details.

- Wire Coil Machines: Similar diversity exists for wire coils (GD400, GW2500, GD600, GS300, GD800), including compactors and strapping options.

- Hose/Pipe Coil Machines: Horizontal (GW400) and high-table (GS200, GS300) options are available, along with automatic pipe coilers.

- Other Coil Types: Dedicated machines for bearings (ZC-300, ZC-2200, GD300) and tyres (GS300, GD300, GS200) demonstrate market segmentation.

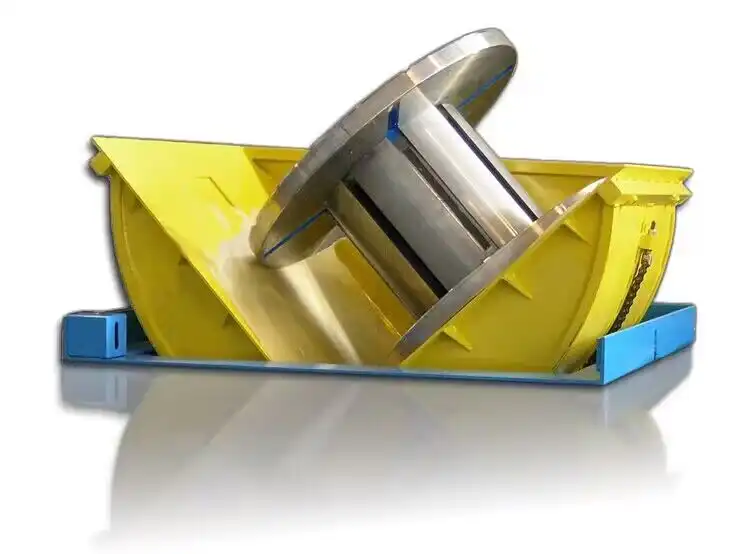

- Related Equipment: Beyond coil wrappers, they offer Pallet Inverters, Upenders & Tilters (Mechanical, Hydraulic), Stretch Wrappers (Pallet, Orbital), Shrinking Machines, Handling Machines (Stackers), and complete Automatic Packing Lines (Coil, Tube, Pipe, Aluminum).

This extensive range allows SHJLPACK to potentially serve customers with varying needs and budgets. A facility requiring a basic, semi-automatic wrapper for occasional use might find a cost-effective solution in their simpler models, while a high-volume steel service center could invest in a fully automated line.

Their claimed 18+ years of experience and 500+ global customers suggest significant market penetration and accumulated expertise. This experience can translate into:

- Refined Designs: Machines potentially optimized for reliability and common industry challenges.

- Application Knowledge: Ability to recommend suitable solutions based on specific customer needs (coil type, size, production flow).

- Standardization: Potential for cost savings through standardized components across different machine types.

- Service Network: Implied capability for installation, service, and parts, although the extent isn't detailed in the provided text.

SHJLPACK emphasizes benefits like replacing manual labor, improving packaging results, and providing customized solutions. From a plant engineering viewpoint, these align with goals of increasing efficiency, reducing operational costs, and ensuring product protection. The availability of options like automatic weighing, printing, tapping, and centering devices allows tailoring the machine's functionality, directly impacting its price but potentially offering significant ROI through enhanced automation and process control. The comparison against manual or semi-automatic methods is a key selling point, highlighting labor cost savings and improved packaging consistency.

Key Factors Influencing Steel Coil Packing Machine Investment

Regardless of choosing FHOPEPACK, SHJLPACK, or another manufacturer, several universal factors critically influence the final price and overall value of a steel coil packing machine investment. Plant engineers must meticulously define their requirements against these factors to obtain accurate quotes and make sound comparisons.

Ultimately, the price of a steel coil packing machine from either FHOPEPACK or SHJLPACK depends critically on core specifications like coil dimensions (ID/OD/Width) and weight capacity, required throughput (target coils per hour or cycle time), the desired level of automation (from manual loading/unloading to fully integrated robotic lines), the choice and combination of packing materials (stretch film, VCI paper, crepe paper, knit tape), and the inclusion of necessary auxiliary functions (automatic weighing, labeling, logo tapping, stacking, tilting, conveying). A thorough understanding and clear definition of these specific operational requirements are paramount before engaging with suppliers for pricing.

Beyond the Sticker Price: ROI, TCO, and Manufacturer Support

While the initial purchase price is a significant factor, a comprehensive evaluation from a plant engineering standpoint must extend to the Total Cost of Ownership (TCO) and Return on Investment (ROI).

TCO Calculation:

- Initial Cost: Purchase price of the machine, including essential options.

- Installation & Commissioning: Costs associated with site preparation, machine setup, integration with existing lines, and initial testing. Both FHOPEPACK and SHJLPACK likely offer these services, but terms and costs may vary.

- Training: Operator and maintenance personnel training costs. Effective training minimizes errors and downtime.

- Consumables: Cost of packing materials (film, paper, tape, straps). Machine efficiency (e.g., FHOPEPACK's mention of film tension control, Lachenmeier's focus on stretch efficiency in competitor lists) impacts material consumption.

- Energy Consumption: Power requirements of motors and control systems (e.g., FHOPEPACK FPS-600 approx. 7.5kw).

- Maintenance & Spare Parts: Routine maintenance schedules, cost of wear parts (rollers, belts, cutters), and availability/cost of critical spares. The quality of components used (emphasized by FHOPEPACK) influences maintenance frequency and cost.

- Downtime Costs: Potential production losses during scheduled maintenance or unexpected breakdowns. Machine reliability is crucial here.

ROI Analysis:

- Labor Savings: Reduction in manual labor required for packing. This is a primary justification highlighted by SHJLPACK. Quantify hours saved and associated wage/benefit costs.

- Throughput Increase: Higher packing speed compared to manual or older methods increases overall plant output capacity. Compare machine cycle times (e.g., 20-30 seconds per coil mentioned for some systems).

- Material Savings: Optimized use of packing materials through better tension control or advanced stretching techniques.

- Reduced Product Damage: Consistent, secure packaging minimizes damage during handling and transit, reducing scrap, rework, and customer claims.

- Improved Safety: Automation reduces manual handling of heavy coils, lowering the risk of workplace injuries and associated costs.

- Enhanced Package Quality: Consistent appearance and protection enhance brand image and customer satisfaction.

Manufacturer Support:

- Technical Support: Availability and responsiveness of technical assistance for troubleshooting.

- Service Network: Geographic reach and speed of service technicians for repairs or maintenance.

- Warranty: Terms and duration of the manufacturer's warranty.

- Customization & Upgrade Path: Manufacturer's ability to support future modifications or upgrades as needs evolve.

Both FHOPEPACK and SHJLPACK appear capable of offering customized solutions. FHOPEPACK details specific optional components like automatic cutters and HMIs. SHJLPACK mentions various options like weighing and centering devices. Evaluating their respective capabilities in consultation, design, manufacturing lead times, and post-sales support is essential. Comparing quotes should involve scrutinizing not just the price but the detailed scope of supply, included features, component specifications (e.g., PLC brand, motor efficiency), warranty terms, and available support structures.

Conclusion

Selecting the right steel coil packing machine involves a detailed comparison that goes far beyond the initial quote. While both FHOPEPACK and SHJLPACK are significant players offering a range of solutions, the optimal choice depends heavily on specific plant requirements. Factors like coil dimensions, required throughput, automation level, desired features, and integration complexity are primary drivers of cost. FHOPEPACK often highlights advanced customization and technology, while SHJLPACK leverages extensive experience and a broad product line. Plant engineers must carefully evaluate the TCO and ROI, considering machine reliability, maintenance, efficiency, and manufacturer support. Ultimately, defining operational needs clearly and obtaining detailed, comparable proposals from both suppliers is crucial to determining the best value and understanding the true steel coil packing machine price in the context of long-term operational success.