Multi-Conveyor has recently completed the construction of a cutting-edge stainless steel table top system. This innovative system is specifically designed to facilitate the rotation of bag-in-box cartons, transitioning them from a wide edge to a narrow edge orientation.

The primary objective of this project was to develop a state-of-the-art solution for efficiently handling and repositioning cartons. By incorporating a rotating mechanism into the system, Multi-Conveyor has successfully achieved this goal. The stainless steel table top system operates smoothly and effectively, ensuring that the cartons are properly oriented for further processing.

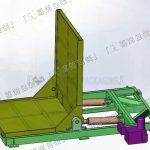

The upender conveyor plays a crucial role in the rotation process. This specialized conveyor is capable of precisely and consistently flipping the cartons, allowing for seamless alignment and repositioning. By implementing this advanced technology, Multi-Conveyor has revolutionized the handling of bag-in-box cartons, streamlining production processes and enhancing productivity.

The upender conveyor can be utilized across various industries and applications. It is particularly beneficial for manufacturers and distributors who deal with bag-in-box products. The innovative design and functionality of this system allow for increased efficiency and accuracy in carton rotation.

In conclusion, Multi-Conveyor’s stainless steel table top system, equipped with an upender conveyor, offers a cutting-edge solution for the rotation of bag-in-box cartons. Its advanced technology and precise operation ensure optimal orientation and efficiency. This system is a game-changer for manufacturers and distributors in need of a reliable and efficient solution for carton rotation. Upender

“Efficient Carton Rotation with Innovative Upender Conveyor Design”

#Upender #Conveyor #Carton #Rotation #Orientation #MultiConveyor